Jan 18 2010

The “Parasols” in Seville feature components that are designed to be glued instead of bolted together. To prevent the adhesive from melting, it needs to withstand temperatures of up to 60 degrees. Researchers have optimized the adhesive's resistance to high temperatures.

Heat-resistant adhesive for building work.

Heat-resistant adhesive for building work.

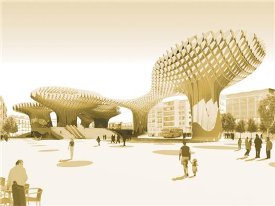

The Metropol Parasols will be the new centerpiece of Plaza de la Encarnación in Seville. As well as being an eye-catching work of art, the mushroom-like structures are also playing host to some pioneering construction techniques, with even the load-bearing structural components consisting of finely-wrought laminated veneer lumber beams. With mechanical joining methods ruled out for structural reasons, the beams are instead joined together by means of glued-in threaded rods. However, the high temperatures and relentless sunshine of a typical Seville summer could pose a significant challenge to the adhesive, in the worse-case it loses its ability to hold the components together.

The type of adhesive used in Seville is designed to withstand temperatures of up to 60 degrees, so researchers from the Fraunhofer Institute for Wood Research WKI have been working on behalf of the building inspection authorities to determine how close the thermal load is likely to come to this limit. “We ascertained the temperatures that might occur at the site and used simulations to determine the temperature this would trigger within the construction materials,” explains Dirk Kruse, head of department at WKI. “Our results revealed that the temperatures in the adhesive could potentially reach almost 60 degrees, which is obviously too close to the limit for comfort.” Subsequent tests carried out on three specimen components in a climate chamber confirmed their findings, giving rise to a stark choice: either the adhesive would have to be improved, or the building inspection authorities would be forced to bring building work to a halt. Fortunately, there is a method of improving the adhesive's resistance to high temperatures, namely by “tempering” the structural components: “Once the components have been glued in place, they are heated up again,” Kruse continues. “This causes post-curing reactions to occur.” And the result? The adhesive is less likely to take on a liquid form and maintains its stability up to a temperature of 70 degrees. This gives a safety margin over and above the thermal stress that is actually expected to occur, which means that the building work can now be continued as planned and Seville will soon be featuring a brand new landmark.

“These are the kinds of solutions that will help to firmly anchor adhesive technology within the building industry,” Kruse states. While adhesive bonding is widely used in the aircraft industry, the use of adhesion for structural applications in the building industry is still in its infancy. Yet the method opens up a whole new wealth of possibilities for architects.