Reviewed by Lexie CornerApr 11 2025

A recent review article in Engineering examines vacuum glazing, a technique that can improve building energy efficiency. As buildings account for around 40 % of total energy consumption, improving the thermal performance of glazing is essential for achieving low-carbon building goals.

Image Credit: Frontiers Journals

Vacuum glazing is gaining attention for its ability to retain heat, provide sound insulation, be lightweight, and resist condensation. While the concept originated in 1913, it was not until 1989 that Australian researchers achieved vacuum glazing with significant thermal insulation properties. Since then, the development of the technology has advanced.

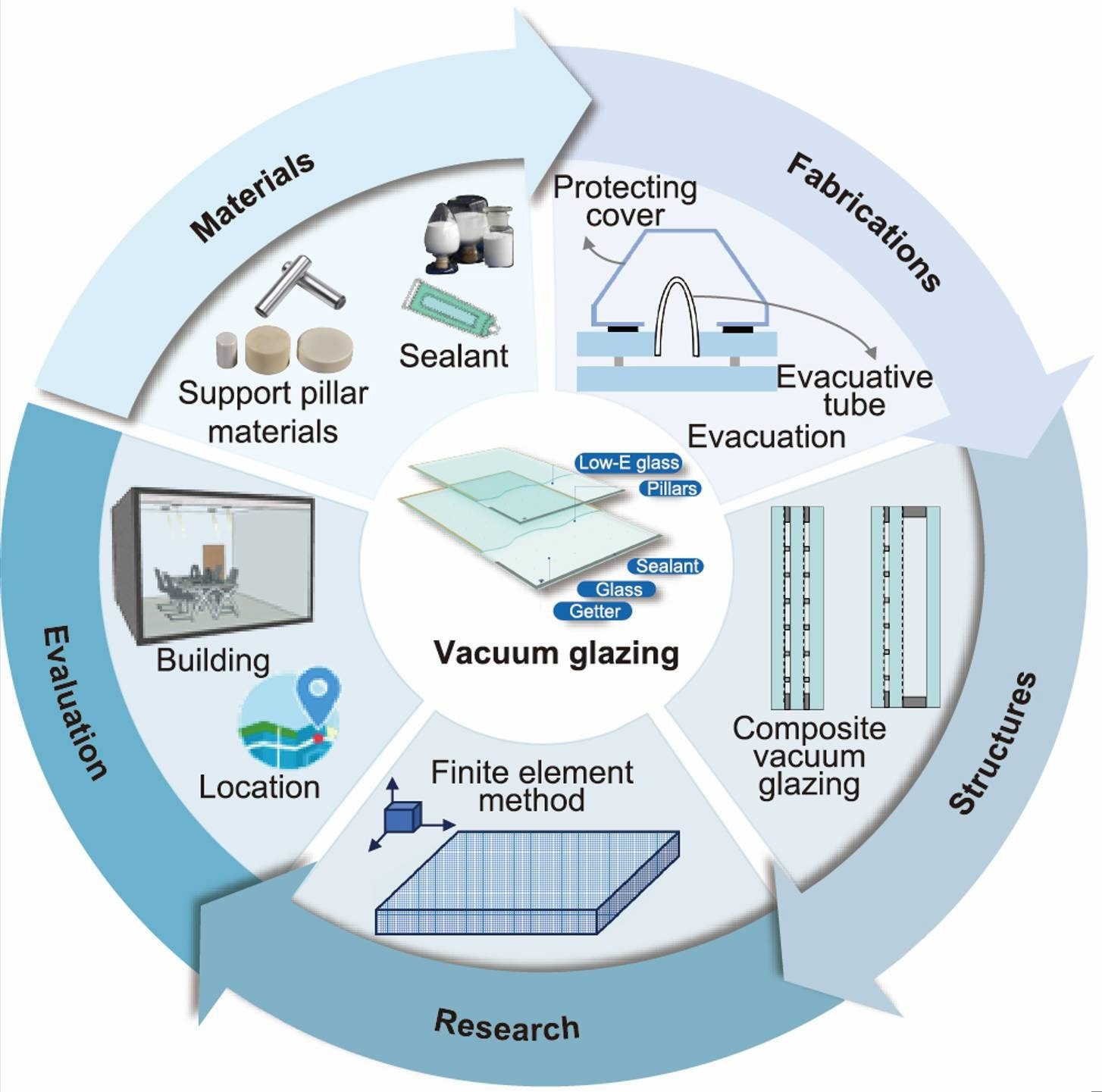

The review covers various aspects of vacuum glazing, including research techniques, composite structures, support pillar configurations, fabrication methods, and energy-saving potential.

Three primary fabrication techniques are discussed: solder glass edge sealing, vacuum chamber edge sealing, and pump-out edge sealing. Although each method has its pros and cons, the modified pump-out method appears most promising, as it addresses issues such as the vacuum chamber method's inadequate outgassing and the high-temperature deterioration seen with glass powder sealing.

Support pillars are crucial for maintaining the vacuum gap and withstanding external pressure. Their arrangement must balance thermal and mechanical factors. There have also been developments in composite vacuum glazing, including hybrid, triple, and PV vacuum glazing. While PV vacuum glazing can provide clean electricity by capturing solar radiation, triple vacuum glazing can achieve a very low U-value, suggesting good insulation performance.

Researchers use experimental, numerical, and analytical techniques to evaluate the thermal performance of vacuum glazing. These methods help in understanding heat transfer mechanisms and in assessing how factors such as glass type, vacuum level, and low-E coating emissivity affect the U-value.

The energy-saving potential of vacuum glazing varies with building type, climate, and other factors. Triple vacuum glazing is particularly effective in minimizing heat loss in cold climates, while PV vacuum glazing can significantly increase energy efficiency in regions with high solar radiation. Tinted vacuum glazing is well-suited for areas with seasonal temperature variations that require heating and cooling.

However, challenges remain. Further research is needed on the stability and industrial scalability of vacuum glazing with aerogel support pillar arrays. Additionally, identifying the best control strategy for tinted vacuum glazing and understanding the aging process of vacuum glazing and its composite structures are essential for optimizing their energy-saving capabilities.

Overall, vacuum glazing has significant promise for helping to produce sustainable, low-carbon buildings.

Journal Reference:

Peng, J. et al. (2025) Excellent Insulation Vacuum Glazing for Low-Carbon Buildings: Fabrication, Modeling, and Evaluation. Engineering. doi.org/10.1016/j.eng.2024.11.027