May 8 2019

Cement is used to build some of the world’s largest structures; however, it appears that it actually has something in common with a sponge.

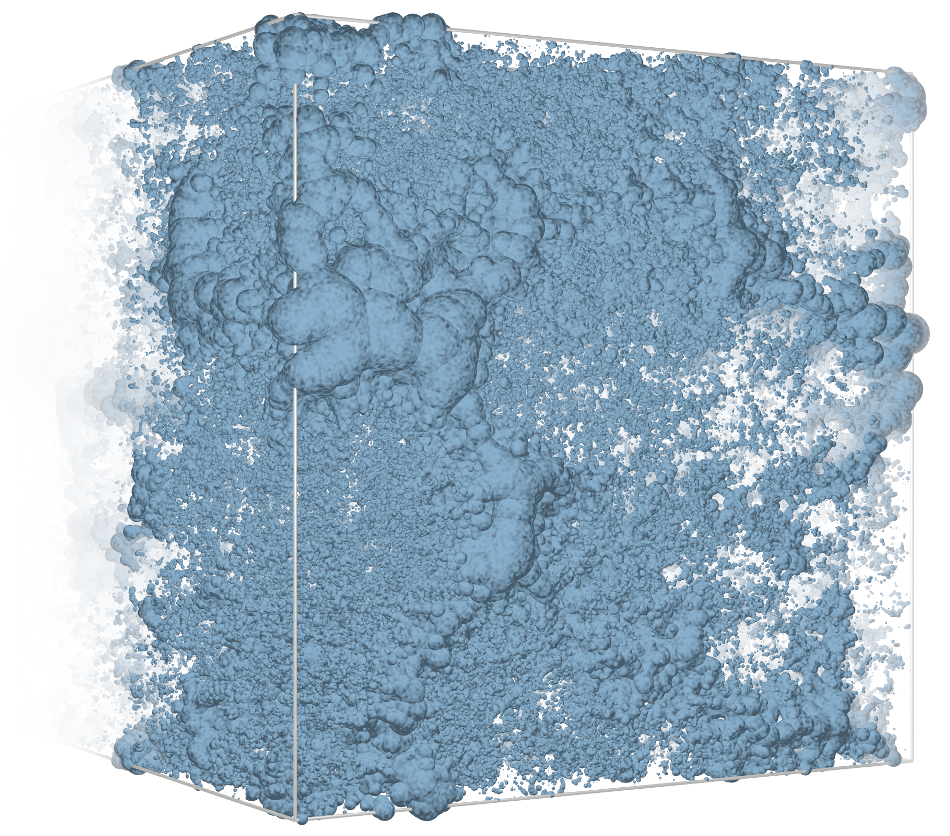

A close-up view of the pore network for a sample of cement. (Image credit: Katerina Ioannidou, et al.)

A close-up view of the pore network for a sample of cement. (Image credit: Katerina Ioannidou, et al.)

Cement is a highly porous material and it tends to absorb water from precipitation and even ambient humidity. Moreover, quite similar to the way in which the shape of a sponge varies based on water saturation, the cement also changes its shape, according to recent work carried out at MIT.

In a paper reported in the Proceedings of the National Academy of Sciences, scientists at the MIT Concrete Sustainability Hub (CSHub), French National Center for Scientific Research (CNRS), and Aix-Marseille University report just how the porous network of the material takes up water and suggest how drying permanently rearranges the material and results in potential structural damage.

However, in order to perceive how water can modify the pore structure of cement, one should first analyze how it contributes to the creation of this very same structure.

Initially, cement paste is a dry powder made up of carefully mixed elements including iron, calcium, silicon, and aluminum. After that, this powder is combined with a definite ratio of water to create cement paste. At this point, the pore network starts to develop.

After the water is blended with the powder, they react together and create compounds called calcium silicate hydrate (CSH), also referred to as cement hydrates.

Cement hydrates are small, on the nanoscale scale. These are the building blocks of cement.

Tingtao Zhou, Study Lead Author and PhD student, Department of Physics, MIT

At the time of cement hydration, the cement hydrate’s nanograins combine with each other, resulting in a network that sticks all ingredients together. This offers strength to the cement, whereas the spaces between the cement hydrates create a wide pore network in the cement paste.

“You have numerous pores of variable sizes that are interconnected,” describes Zhou. “It becomes very complex. And since they are so small, you don’t even need rain to fill them with water. Even ambient humidity can fill these pores.”

This causes an issue when attempting to analyze the drying of a pore network.

“Let’s say you only have two grains of calcium silicate hydrate; you can imagine there is some water condensation between them,” explains Zhou. “In this case, it is easy to measure the water in the pore space and the pressure of this condensation, which we call capillary pressure. But when you have a massive number of grains the water distribution becomes really complicated—the geometry becomes a mess.”

To manage water in the messy pore network of the cement, Zhou and Katerina Ioannidou, a research scientist with CNRS and the MIT Energy Initiative and a corresponding author of the paper, first fought with two challenges.

The first challenge was partial saturation. Due to the very intricate pore network, water is not uniformly distributed, making it hard to analyze its distribution.

The second challenge is that of multiple scales.

In the past, researchers would study the movement of water in pores at either the scale of the atom or on the continuum, or visible, scale. This means they lost a lot of information on the mesoscale—which is between the atomistic and continuum scales.

Tingtao Zhou, Study Lead Author and PhD student, Department of Physics, MIT

For the last 10 years, Ioannidou, together with scientists Roland Pellenq, Franz-Josef Ulm, Sidney Yip, and Emanuela Del Gado of Georgetown University, has worked to improve the modeling of cement at multiple scales. This recent paper utilized their work to deal with these problems.

Zhou and Ioannidou employed computational modeling techniques to calculate how water disperses within a pore and then established the force exerted by the water on the pore wall. After completing this, they assembled pores together and simulated the effect of drying on the mesoscale.

After observing the simulations, Zhou and Ioannidou realized that the grains had “irreversibly rearranged under mild drying.”

While these alterations seemed small, they were not necessarily trivial. “We found irreversible structural changes on the mesoscale,” Zhou notes. “It’s not propagating to a larger scale yet. But what happens when we have many of these drying cycles over many years?”

It is too early to understand how exactly this sort of structural variation influences concrete structures; however, Zhou expects to build a new model to investigate the long-term effects of drying.

“In this paper, we have dealt with different spatial scales. But we have yet to deal with different time scales. These changes occur in a period of nanoseconds and we would like to see their influence over the typical lifetime of concrete structures,” he explains.

Nevertheless, this computational method offers a new path to gain better insights into the consequences of drying in cement.

In past physical experiments, it is very hard to observe damage on this scale. But computation enables us to simulate this kind of damage. This is the power of computing.

Tingtao Zhou, Study Lead Author and PhD student, Department of Physics, MIT

The MIT Concrete Sustainability Hub (CSHub) is a group of scientists from various departments across MIT working on concrete and infrastructure science, engineering, and economics. Their work is supported by the Portland Cement Association and the Ready Mixed Concrete Research and Education Foundation.