Sep 13 2016

GreenMantra Technologies, a rapidly growing producer of high-value waxes from recycled plastics, is introducing to the roofing industry its line of Ceranovus wax modifiers designed to improve asphalt roofing manufacturing and performance.

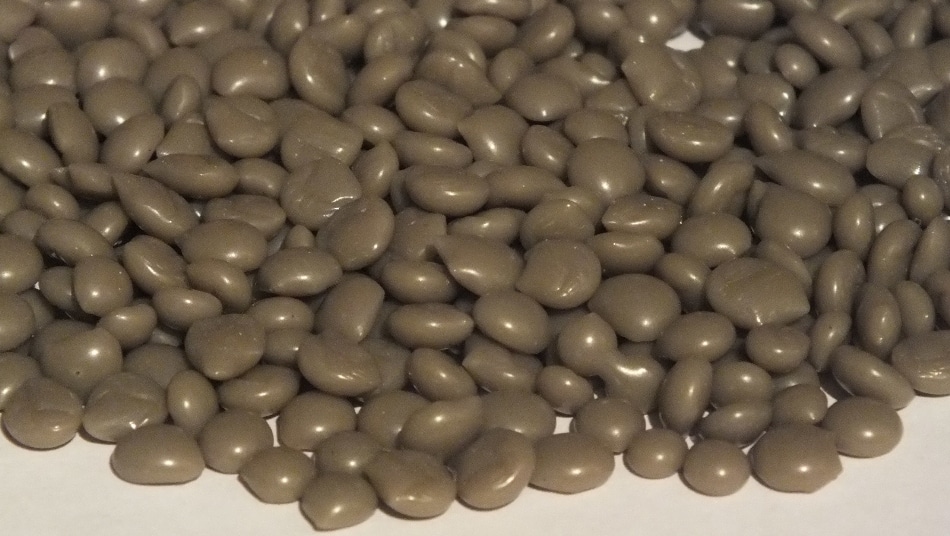

GreenMantra Technologies' Ceranovus waxes are designed specifically for asphalt roofing applications. (PRNewsFoto/GreenMantra Technologies)

GreenMantra Technologies' Ceranovus waxes are designed specifically for asphalt roofing applications. (PRNewsFoto/GreenMantra Technologies)

The Ceranovus polyethylene and polypropylene waxes are designed specifically for asphalt roofing applications and can be customized for unique formulations. When used as a modifier in the manufacture of roofing products, tests and actual line performance demonstrate Ceranovus waxes can:

- Improve line speed and processing times

- In polymer modified applications, reduce mixing times buy 30%

- Decrease viscosities at process temperature

- Reduce bleeding of higher oil formulations through oil scavenging

- Stabilize or increase softening point

- Decrease penetration without impacting cold temperature performance

- Reduce oxidation times and emissions in air blowing and oxidation applications.

Ceranovus waxes are valuable additives in both SBS (styrene-butadiene-styrene) and APP (atactic polypropylene) modified bitumen roofing systems. The waxes help to reduce the mixing time necessary to completely blend the polymer, improve heat stability, and greatly improve resistance to deformation in roll or shingle.

Ceranovus waxes are synthesized from 100 percent recycled materials, providing the added benefit of a sustainable, environmentally suitable raw material to enhance the environmental profile of finished roofing products.

Ceranovus wax is available in pastilles or granules, with packaging available in 45-pound bags, or gaylords and supersacks.