Jun 4 2014

New Energy Technologies, Inc., developer of see-through SolarWindow™ coatings capable of generating electricity on glass and flexible plastics, today released first-ever power modeling estimates of its SolarWindow™ prototype modules.

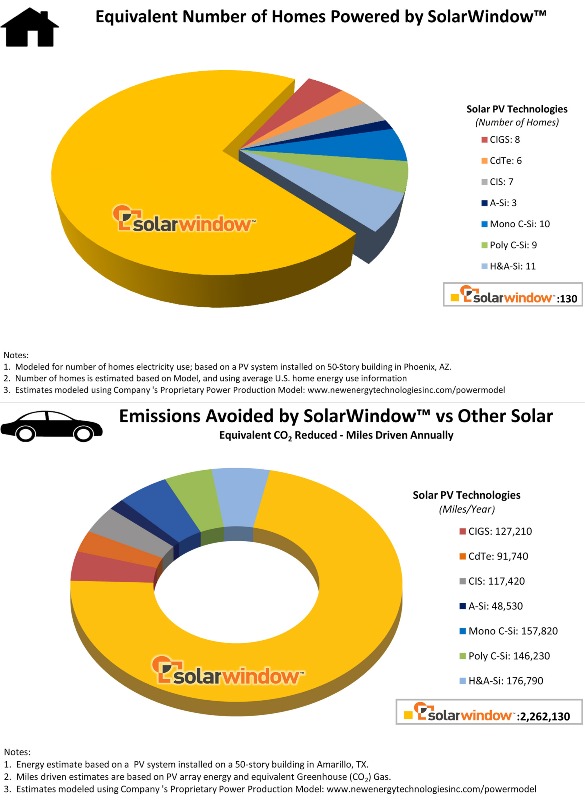

Key to typical Solar PV Technologies referenced in the Charts: CIGS: Copper Indium Gallium Selenide; CdTe: Cadmium Telluride; CIS: Copper Indium Selenide; A-Si: Amorphous Silicon; Mono C-Si: Monocrystalline Silicon; Poly C-Si: Polycrystalline Silicon, and; H&A-Si: Hybrid Monocrystalline & Amorphous Silicon. (Graphic: Business Wire)

Key to typical Solar PV Technologies referenced in the Charts: CIGS: Copper Indium Gallium Selenide; CdTe: Cadmium Telluride; CIS: Copper Indium Selenide; A-Si: Amorphous Silicon; Mono C-Si: Monocrystalline Silicon; Poly C-Si: Polycrystalline Silicon, and; H&A-Si: Hybrid Monocrystalline & Amorphous Silicon. (Graphic: Business Wire)

Engineers estimate that SolarWindow™ modules could conservatively produce at least ten times the electrical energy of conventional rooftop photovoltaic (PV) systems, and in some instances, exceed power performance by as much as 50-fold. SolarWindow™ modules could also eliminate the equivalent carbon dioxide (CO2) emissions produced by vehicles driving more than 2 million miles per year.

Recently, New Energy’s largest, high-performance SolarWindow™ module set a new “certified” record for generating electricity while remaining see-through; SolarWindow™ high-performance prototype produced over 50 percent greater power than prior attempts publicized by others of comparable organic photovoltaic (OPV) prototype device architecture, size and design.

Using the independently tested and certified power production data for its SolarWindow™ modules from the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL), Company engineers have since developed a model for estimating the amount of electrical energy and environmental benefits SolarWindow™ prototype modules may provide.

In every instance where New Energy’s high-performance prototype SolarWindow™ modules have been modeled for performance against today’s typical rooftop solar PV module systems, the modeling estimates show significantly greater generation of electrical energy and multiple-fold environmental benefits.

By way of illustration, the Company model estimates show that when installed on all four sides of a 50-story building in:

- Phoenix, Arizona – SolarWindow™ modules could generate enough electricity to power 130 homes each year. Today’s rooftop systems could only produce enough for 3 to 11 homes per year.

- Amarillo, Texas – SolarWindow™ modules could provide the equivalent of avoiding the CO2 emissions produced by vehicles driving over 2.2 million miles each year. Today’s rooftop systems could only avoid the equivalent CO2 emissions produced from 49,000 to 180,000 miles of vehicle miles per year.

- Miami, Florida - SolarWindow™ modules could generate over 1.3 million kWh (kilowatt hours) of energy. Today’s rooftop systems could only generate from 28,000 to 102,000 kWh.

- Denver, Colorado – SolarWindow™ modules could provide the equivalent reductions in CO2 emissions produced by as much as 770 acres of forest sequestering CO2. Today’s rooftop systems could only provide the equivalent CO2 reductions produced by 20 to 70 acres of forest sequestering CO2.

“High power output and meaningful environmental benefits are among the most important drivers for our potential commercial customers, strategic partners, and end consumers,” explained Mr. John Conklin, President and CEO of New Energy Technologies, Inc. “We now have a model that estimates SolarWindow™ module performance in these key areas, and compares these estimates to today’s conventional rooftop solar PV module systems.”

“Importantly, we’ve long believed in the electrical power production and environmental benefits of applying our see-through SolarWindow™ coatings to the many acres of glass windows on all four sides of commercial tall towers and skyscrapers, rather than relying on limited rooftop space available for today’s conventional solar PV rack-mounted systems. Our decision to pursue vast glass surfaces on buildings to create environmentally friendly energy producing power plants shows its benefits in our latest modeled estimates.”

Today’s modeled estimates were developed exclusively by New Energy Technologies’ engineers and researchers. The Company’s internal teams modeled their calculations based on results of independent testing and certification of its record-setting SolarWindow™ high-performance modules by the NREL Device Performance Measurement Laboratory. The Device Performance group is one of only two laboratories in the world to hold an International Organization for Standardization (ISO) 17025 accreditation for primary reference cell and secondary module calibration, in addition to accreditation for secondary reference cell calibration under American Society for Testing Materials (ASTM) and International Electrotechnical Commission (IEC) standards.

SolarWindow™ is currently under development for eventual commercial deployment in the estimated 80 million detached homes in America and more than five million commercial buildings. The technology is the subject of 42 patent filings, and researchers are on track to advance SolarWindow™ towards full-scale commercial manufacturability – a near-term goal.