|

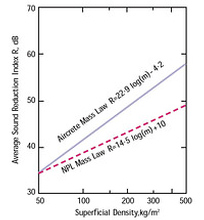

Test data has proved that a wall constructed from Celcon aircrete blocks can match the acoustic performance of brick and aggregate block masonry walls. This is demonstrated in the graph which shows a superior mass law curve for aircrete compared with the NPL mass law relationship which applies to all other forms of masonry. The graph shows the sound reduction index R for a known superficial density of the two types of masonry.

It clearly demonstrates how an aircrete separating party wall although lightweight, can equal the heavy constructions of similar thickness.

Sound Insulation Relationship

Experience has shown that there is a relationship between the various factors which contribute to good sound insulation:

Careful design + Separating-wall construction + Associated structure + Proper site practice

= Good sound insulation

and a deficiency in just one part can adversely affect the overall performance. The most common fault is poor workmanship, e.g. poorly filled joints.

Principles when Developing Design Details

The Celcon Technical Services Department is pleased to discuss any sound insulation queries.

It is recommended that the designer always follows these principles when developing design details:

1. Wherever possible, rooms either side of a separating wall should have similar uses.

2. Ideally services should not pass through, or be chased into, separating walls.

3. Mechanical equipment (such as cooker hoods, boilers and pumps) should never be mounted on a separating wall, unless fixed on acoustic mountings.

4. In the design of the structure, sound transmission can be reduced if:

a) The floor slab supporting the separating party wall is not continuous,

b) Joists are not built into the separating wall (if this is unavoidable they should be fully sealed),

c) Wall ties in cavity separating walls are omitted if they are not required structurally.

5. Movement joints should not be built into separating party walls.

6. Steps and staggers between dwellings will improve sound insulation.

|