By Nidhi DhullReviewed by Susha Cheriyedath, M.Sc.May 7 2024

By Nidhi DhullReviewed by Susha Cheriyedath, M.Sc.May 7 2024A recent article published in Construction Materials explored the use of mattress waste materials for building insulation, aiming to mitigate waste generation in the construction industry. It specifically focused on polyurethane foam (PUF) from mattresses and comprehensively analyzed its thermal performance against the industry standards.

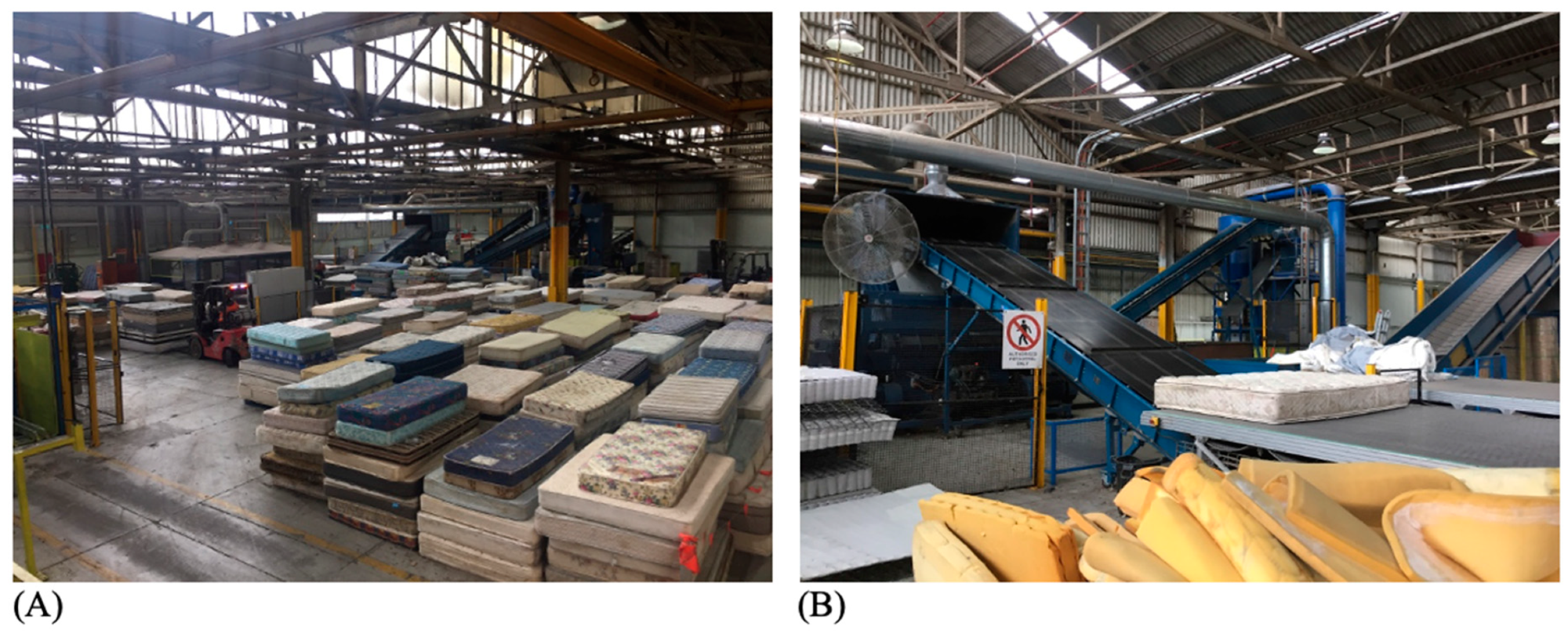

TIC Group Recycling Plant (A) Mattress (B) Conveyor belt. Image Credit: https://www.mdpi.com/2673-7108/4/2/22

TIC Group Recycling Plant (A) Mattress (B) Conveyor belt. Image Credit: https://www.mdpi.com/2673-7108/4/2/22

Background

The construction industry is a major consumer of natural resources and a significant producer of waste. Consequently, several strategies are being developed to improve the management of these materials. One promising approach involves the use of novel thermal insulation materials, which can significantly reduce the industry's energy consumption by enhancing indoor thermal environments and decreasing reliance on heating and cooling systems.

The insulating properties of a material depend on its physical composition and cellular structure. Commonly used insulation materials include fiberglass, polyester, natural wool, glass wool, rock wool, and polystyrene, each chosen based on its insulation effectiveness. Among these, spray polyurethane foam (PUF) is widely utilized; however, it contributes to substantial carbon emissions, adversely affecting the environment.

In line with the global move toward sustainable construction and a circular economy, there is an increasing integration of waste materials into building products. Currently, waste mattress PUF is not employed in the construction sector nor fully recycled, primarily due to issues of contamination, fire safety, and end-of-life disposal. This study explores the potential re-use of waste mattress PUF as an insulation material, aiming to contribute to more sustainable construction practices.

Methods

In this research, the team conducted a bibliometric analysis using Bibliometrix to identify the waste materials most frequently used as insulation in the construction and building sector from 1991 to 2023. Among the various recycled materials examined for building applications, the study specifically investigated the insulation capabilities of waste PUF from mattresses, which typically remain unrecycled.

The researchers sourced waste mattress PUF specimens from a facility operated by TIC Group, a leader in mattress recycling based in Victoria, Australia. They evaluated the thermal properties of these specimens using the transient plane source (TPS) technique. Given that TPS results for low-density materials like PUF correspond closely with their insulation values, this method was deemed appropriate. The thermal studies involved varying the thickness of the PUF samples and adjusting parameters for low thermal conductivity.

Additionally, the study looked into current trends in insulation materials, along with the challenges and future potential for using waste mattress PUF in sustainable building practices.

Results and Discussion

The review of 2,627 publications highlighted that foam, mortar, and clay are the least researched materials for waste insulation, while fiber and fly ash have received considerable attention. The investigation into the use of waste from mattresses for insulation in the construction sector revealed that it is rarely considered.

PUF is a thermosetting plastic created by combining various chemicals, renowned for its durability, comfort, and support in mattresses. Its properties also include sound absorption, fire retardation, and thermal resistance, making it a strong candidate for thermal insulation in building construction. However, during a site visit to the TIC Group, researchers observed that about 2-3 tons of shredded mattress materials, including PUF, are sent to landfills each day.

Materials with low thermal conductivity are crucial for improving energy efficiency and minimizing heat loss in buildings and industrial settings. Nonetheless, the thermal conductivity of the examined PUF mattress waste determined using the TPS technique was higher than that of commercially available insulation materials.

Despite this, with further material engineering, mattress waste PUF could be used as building insulation. TPS analysis at low power output and extended measurement durations indicated that PUF, at a thickness of 215 mm, achieved optimal thermal resistance in line with industry standards for building fabrics.

However, PUF also presents challenges that restrict its recycling and reuse. It is highly flammable and emits extremely toxic hydrogen cyanide and isocyanates when burned. Therefore, integrating eco-friendly additives and flame-retardant polymers is essential to mitigate fire hazards and health risks, thus enhancing its potential for reuse.

PUF has various applications in construction. For example, polyurethane powder, created by grinding the foam, can be incorporated into concrete to enhance its insulating properties. In Japan, this ground material is used in mortar and as a lightweight aggregate in roof construction.

In conclusion, the study suggests that recycled mattress PUF can be used effectively as an insulation material in walls and ceilings, achieving the R-values required by the National Construction Code in Australia, and can compete with traditional insulation products in the construction industry.

Conclusion

This study conclusively demonstrated that recycled PUF from mattresses has significant potential as an insulation product, addressing the dual challenges of managing waste materials destined for landfills and reducing resource consumption in the construction industry. It also highlighted existing research gaps concerning waste material sources with potential insulation applications for buildings.

Beyond its insulating properties, the effective cellular structure of PUF provides additional benefits, such as soundproofing. Furthermore, PUF can be combined with various recycled textiles to produce an enhanced insulating material. The authors recommend further research into the moisture resistance and fire retardation properties of waste mattress materials to facilitate their commercial adoption. This could pave the way for broader use in building applications, contributing to more sustainable construction practices.

Journal Reference

Haigh, R. (2024). A Review and Thermal Conductivity Experimental Program of Mattress Waste Material as Insulation in Building and Construction Systems. Construction Materials, 4(2), 401–424. https://doi.org/10.3390/constrmater4020022, https://www.mdpi.com/2673-7108/4/2/22

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.