Rice University researchers have found a method to engineer wood to trap CO2 with a likely scalable, energy-efficient approach.

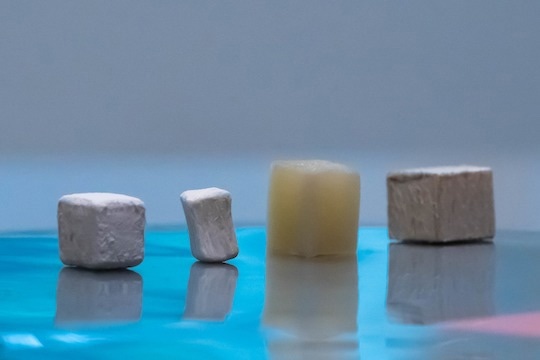

Wood pieces at different stages of modification, from natural (far right) to delignified (second from right) to dried, bleached, and delignified (second from left), and MOF-infused functional wood (first on the left). Image Credit: Gustavo Raskosky/Rice University.

Wood pieces at different stages of modification, from natural (far right) to delignified (second from right) to dried, bleached, and delignified (second from left), and MOF-infused functional wood (first on the left). Image Credit: Gustavo Raskosky/Rice University.

Structural materials, such as cement or steel, can be expensive and contribute to carbon dioxide emissions; construction, as well as its usage, contributes to a probable 40% of emissions. Creating sustainable substitutes to available materials could aid in lessening climate change and decreasing carbon dioxide emissions.

Muhammad Rahman, a materials scientist, and collaborators worked jointly to address both concerns simultaneously. They discovered a technique to incorporate molecules of a carbon dioxide-trapping crystalline porous material into the wood. This study was reported in Cell Reports Physical Science.

Wood is a sustainable, renewable structural material that we already use extensively. Our engineered wood did exhibit greater strength than normal, untreated wood.

Muhammad Rahman, Materials Scientist, Rice University

To succeed in this endeavor, firstly, the cellulose fibers’ network that offers strength to its wood is cleared out by a method called delignification.

Wood is made up of three essential components: cellulose, hemicellulose, and lignin. Lignin is what gives wood its color, so when you take lignin out, the wood becomes colorless. Removing the lignin is a fairly simple process that involves a two-step chemical treatment using environmentally benign substances. After removing the lignin, we use bleach or hydrogen peroxide to remove the hemicellulose.

Muhammad Rahman, Materials Scientist, Rice University

Secondly, the delignified wood is soaked in a solution that contains microparticles of a metal-organic framework (MOF) called Calgary framework 20 (CALF-20). MOFs are high-surface-area sorbent materials that are employed for their capacity to adsorb CO2 molecules into their pores.

The MOF particles easily fit into the cellulose channels and get attached to them through favorable surface interactions.

Soumyabrata Roy, Study Lead Author and Research Scientist, Rice University

MOFs are one of the many nascent carbon capture approaches made to concentrate anthropogenic climate change.

“Right now, there is no biodegradable, sustainable substrate for deploying carbon dioxide-sorbent materials. Our MOF-enhanced wood is an adaptable support platform for deploying sorbent in different carbon dioxide applications,” added Rahman.

Roy stated, “Many of the existing MOFs are not very stable in varying environmental conditions. Some are very susceptible to moisture, and you don’t want that in a structural material.”

However, CALF-20—developed by the University of Calgary Professor George Shimizu and co-workers—is unique with regard to performance level and versatility in different environmental conditions, Roy added.

“The manufacturing of structural materials such as metals or cement represents a significant source of industrial carbon emissions. Our process is simpler and ‘greener’ in terms of both substances used and processing byproducts. The next step would be to determine sequestration processes as well as a detailed economic analysis to understand the scalability and commercial viability of this material,” Rahman concluded.

In Rice’s George R. Brown School of Engineering, Rahman is an assistant research professor in Materials Science and Nanoengineering. Roy is a research scientist in Materials Science and Nanoengineering at Rice.

The research was funded by Shell Technologies (R66830) and the UES-Air Force Research Laboratory (G10000097).

Journal Reference:

Roy, S., et al. (2023) Functional wood for carbon dioxide capture. Cell Reports Physical Science. doi.org/10.1016/j.xcrp.2023.101269.