One of the biggest challenges that humans face is alleviating climate change. Currently, a team of scientists at Worcester Polytechnic Institute (WPI) has created a totally new material that is an economical, high-impact sustainable solution to address one of the biggest contributors to climate change — concrete.

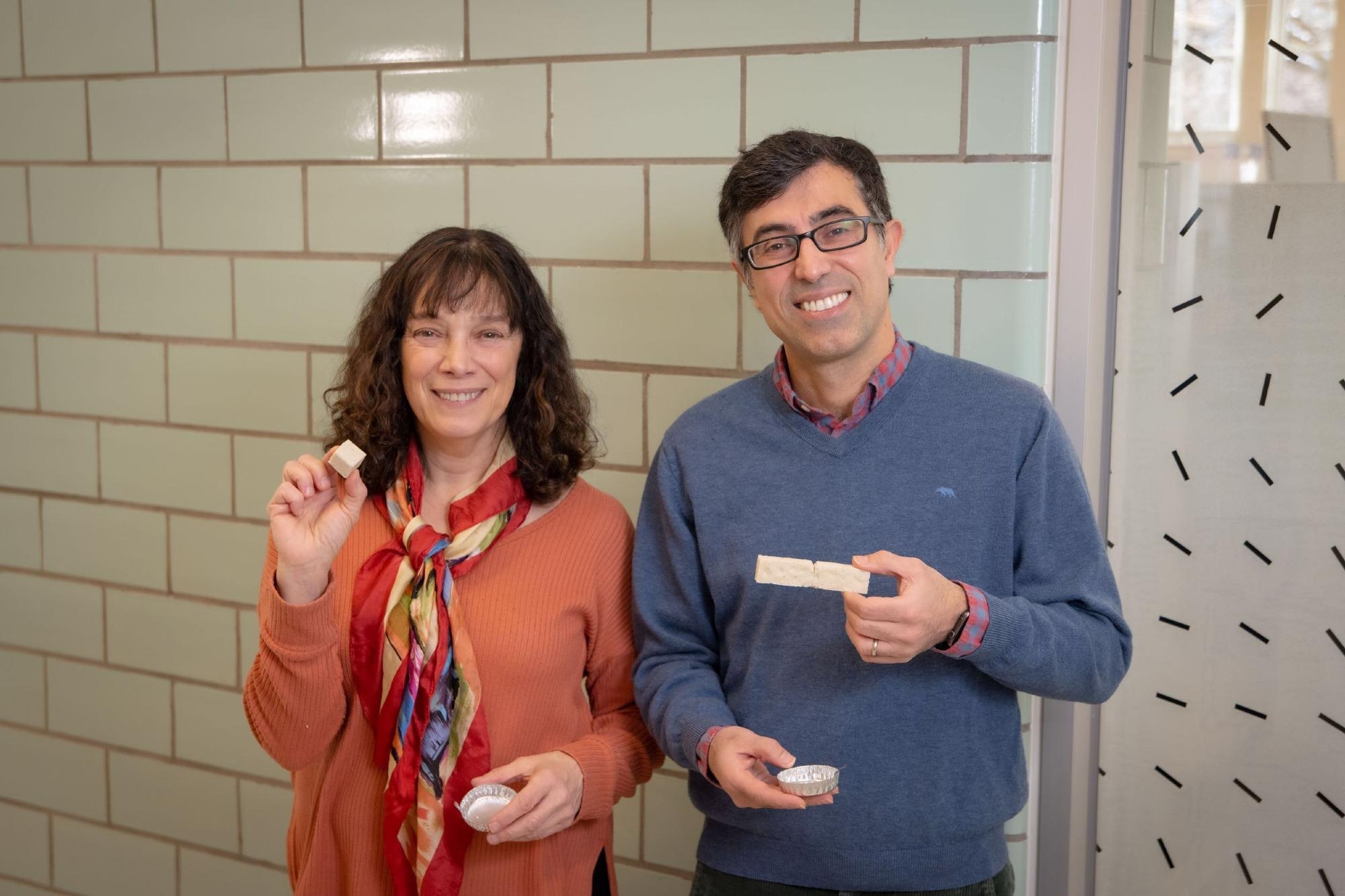

WPI Professors Suzanne Scarlata and Nima Rahbar hold samples of Enzymatic Construction Material. Image Credit: MATT BURGOS.

WPI Professors Suzanne Scarlata and Nima Rahbar hold samples of Enzymatic Construction Material. Image Credit: MATT BURGOS.

According to Statisa, global cement production between 1995 and 2020 increased from 1.39 billion to 4.1 billion tons, making it the second most extensively used material on Earth next to water. As concrete is ubiquitous and has high carbon dioxide (CO2) emissions, an alternative is required.

Humanity needs to come up with an alternative to concrete.

Nima Rahbar, Associate Professor of Civil, Environmental, and Architectural Engineering, Worcester Polytechnic Institute

As reported in the journal Matter, the study at WPI has resulted in the creation of a self-healing Enzymatic Construction Material (ECM), which the research team illustrates as a “living material” that “provides a pathway to repair or even replace [traditional] concrete in the future.”

Biological enzymes are catalysts that stimulate chemical reactions. The material uses an enzyme, called carbonic anhydrase that is present in all living cells.

Carbonic anhydrase efficiently reacts with CO2, and “has the unique ability to rapidly remove the greenhouse gas from the atmosphere. This property has allowed us to formulate a carbon-negative material that we hope may ultimately replace concrete,” explains Richard Whitcomb Professor of Chemistry and Biochemistry Suzanne Scarlata.

ECM is produced through a process involving an enzyme reaction that develops calcium carbonate crystals, which serve as the main ingredient of the material. Sand slurry is also incorporated into the material, as well as a polymer, which keeps the material together during its primary stages, just like scaffolding does during the construction of a building.

The material is also capable of healing itself if cracks form from wear and tear over time, or from other damage, preserving its strength through nearly six self-healing cycles.

This study is the result of an interdisciplinary collaboration between Rahbar, Scarlata, and Ph.D. student Shuai Wang. The team earlier developed a new type of self-healing concrete.

The unique negative emission construction material goes a step further, substituting concrete to form a totally new substance that is, in part, developed from CO2: CO2 enters into the material during its creation, and the material also absorbs CO2 during the self-healing process.

In fact, the team came up with a calculation that reveals “one cubic yard of ECM stores 18 pounds of CO2, while one cubic yard of concrete emits 400 pounds of CO2,” says Rahbar.

Through wide-ranging testing and experimentation, the researchers learned that the material has what they define as “outstanding” compression strength, surpassing traditional mortar, making it adequately robust to be employed in the construction of buildings or bridges as compressive elements.

In contrast to traditional brick, it also does not necessitate baking at high temperatures, and it can be manufactured quickly, unlike the 28 days required to cure concrete. ECM can also be manufactured economically as the percentage of the enzymes is very small.

While ECM may not be seen at a construction site straight away, it may not be long before that takes place. The researchers plan to move the material out of the lab in the near future, first by improving the properties of ECM by “optimizing the catalytic efficiency of enzymes, the property of scaffolds, and the mechanics of crystal structure,” and then by beginning to commercialize the product.

Journal Reference:

Wang, S., et al. (2022) A self-healing enzymatic construction material. Matter. doi.org/10.1016/j.matt.2021.12.020.