Mar 23 2021

A pioneering UK-based steel construction system is on course to dominate the potentially lucrative global nuclear Small Modular Reactor (SMR) market following the successful delivery of a blast chamber contract with a leading US university.

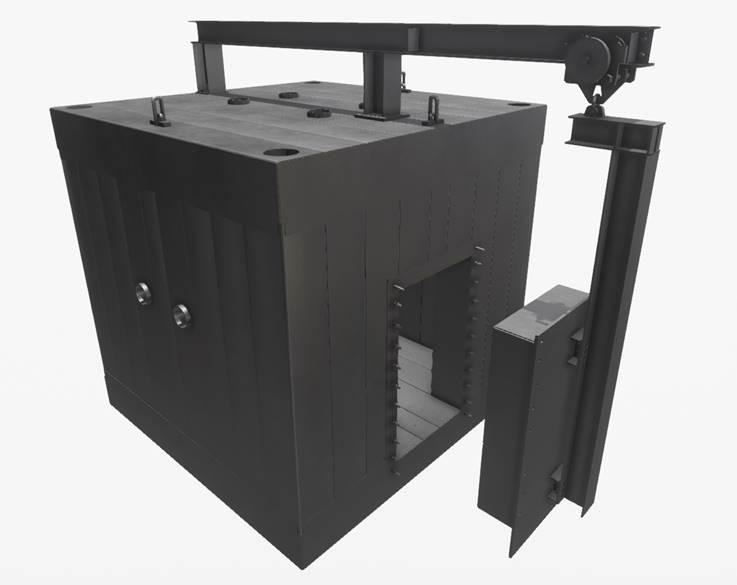

A graphic of the MWS Blast Box. Image Credit: Modular Walling Systems Limited

A graphic of the MWS Blast Box. Image Credit: Modular Walling Systems Limited

The Steel Bricks™ modular construction system developed by Modular Walling Systems Ltd, based in Renfrewshire, Scotland, has been used to construct an Environmental Blast Chamber for the University of Illinois at Urbana-Champaign. Known as a ‘blast box’, the revolutionary ultra-strong three-metre cubed chamber is now being used for explosives testing as part of a research programme on advanced warhead technologies for the US Department of Defense.

The University of Illinois blast box uses the patented Steel Bricks™ modular construction system which comprises two steel face plates internally connected to create a ‘sandwich’ panel. The steel structure is then manufactured off-site as a single piece, before being filled with 72 tons of self-consolidating concrete in a continuous pour once installed. According to Dr. Stewart Gallocher, founding director of Modular Walling Systems, it is this proprietary process which gives the blast box its unique strength - as well as vastly reducing on-site time and labour costs - making it ideal for SMR construction, a market estimated to be worth US $1.2 trillion globally.

He explains: “The Steel Bricks™ system, with trademark diaphragm holes running through the webs, has been assembled in such a way that the concrete is poured through holes in the roof, flowing down the walls and filling the base mat before coming back up the walls and lining the ceiling – all in one continuous pour. This is a ‘first of a kind’ concept in the fast-emerging world of steel composite construction and proves that the Steel Bricks™ system can provide not only the walls and suspended floors or roofs in steel composite but most importantly a base mat. This takes away the need for conventional foundations, eliminating the traditional Achilles Heel of this form of construction which are the weak points of the base mat to wall connection.”

“Many attempts have been made during the past 25 years to devise simple, safe and rapid fabrication methods to internally connect steel faceplates. But most have lacked commercial application due to being too expensive and labour intensive. We have now proved we can successfully deliver a solution which is technologically proficient whilst providing significant cost and time saving benefits.”

The Environmental Blast Chamber was fabricated in the UK by Caunton Engineering, one of the UK’s leading structural steelworks manufacturers, at the company’s manufacturing headquarters in Nottingham before being shipped to the University of Illinois at Urbana-Champaign. Now installed, the blast box is expected to deliver some impressive results, as testified by Professor Nick Glumac who leads the explosive testing and weapons research faculty at the University. He says: “The test facility allows for large scale high explosive testing with advanced imaging, spectroscopic and flash x-ray diagnostics. The system can be operated as a fully enclosed or partially vented structure enabling a wide variety of tests of high explosives, propellant systems and pyrotechnics.

“The chamber has optical access on three sides for multiple views of testing, while internal walls are amenable to instrumentation and fragmentation shields, allowing the testing of heavily fragmenting warheads. The main advantage of the blast box is that it can be ‘dropped-in’ on site, arriving fully assembled and ready for the concrete pour. This means less site preparation, fewer personnel needed for installation and rapid times from delivery to first operation.”

Caunton Engineering and Modular Walling Systems are now in detailed discussions with potential customers about a broad range of applications for the Steel Bricks™ system - including the global nuclear industry. Dr Gallocher continues: “The success of the University of Illinois contract shows that the Steel Bricks™ system is perfectly suited for markets where potentially dangerous materials are being handled and where time on site needs to be minimised. We believe that this technology, combined with the significant cost and time reductions of off-site manufacture, will now provide a major stimulus for the global roll out of Small Modular Reactors.”