Mar 2 2021

Scientists from the Polytechnic University of Valencia (UPV) have developed and patented a new system for making beams, the goal of which is to revolutionize the civil engineering, construction and architecture sectors.

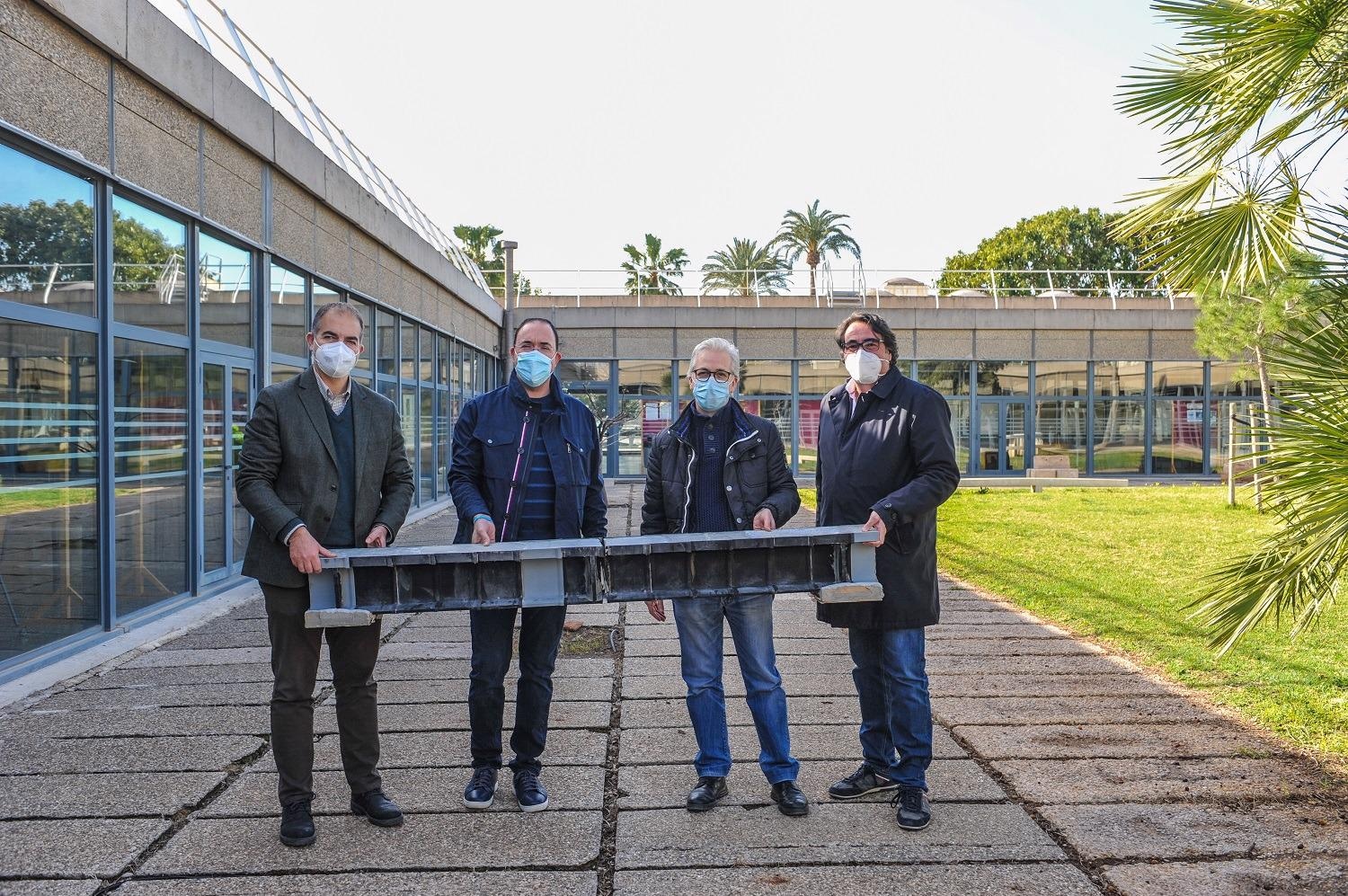

Image Credit: RUVID.

The beams are fabricated with 3D-printed plastic pieces that can be assembled as if they were pieces of Lego including a high performance layer of concrete in the majority of the compressed area.

The researchers who created the new system state that they have numerous benefits: they weigh nearly 80% less than metallic or concrete beams, so no huge cranes or lorries are required to carry and install them; they save money and time on labor and materials; and they can be printed and assembled in situ, which enables them to be installed at any place, irrespective of how hard it is to reach.

Additionally, they make use of recycled plastics as the raw material, thereby providing a new life to this product and hence helping move toward more long-lasting construction.

Nearly three years of research was done to develop such novel beams.

Our goal was to propose an alternative to the current reinforced concrete beams. These are made using profiles built for the length of the piece, which requires expensive installation and are hard to transport.

José Ramón Albiol, Lecturer, Higher Technical School of Construction Engineering, Polytechnic University of Valencia

After executing several hours of tests and trials, the blend of 3D concrete, plastics, and printing offered the most ideal results. Moreover, the system was patented in October 2020.

The principal novelty of the system is the polymeric profile of the beam, which is made of several longitudinal segments that can be assembled and concreted where people desire to install the structure. The beam is strengthened with elements that guarantee the sturdy nature of the structure, without any metallic component.

This prevents corrosion, decreases the weight and simplifies the work time required.

Xavier Mas, Institute for Heritage Restoration, Polytechnic University of Valencia

The system eliminates the need for expensive formwork and bending, making it viable to work without stopping traffic at the infrastructure that is being worked on.

Furthermore, this solution makes it possible to decrease the required labour and auxiliary means, which entails cost and time savings.

José Luis Bonet, University Institute of Concrete Science and Technology, Polytechnic University of Valencia

A 'Human' Structure

One more innovative aspect of the system is the polymeric profiles’ internal structure.

“It is an alveolar structure, which makes it possible to decrease the amount of plastic used – and therefore its weight – while maintaining structural rigidity,” stated Albiol.

This inspiration for the alveolar structure was from human bones present near the epiphysis, where there is a layer of cancellous bone with a trabecular disposition—the alveolar structure—and a thicker external layer of smaller bone.

“This is what we have transferred to these revolutionary beams, specifically to their profiles. It is a very intelligent natural system and its reproduction in these beams awards them, with the low structural weight, very high mechanical capabilities,” José Ramón Albiol added.

Customized Pieces Anywhere

With 3D printing, it is feasible to manufacture tailored pieces closer to the area of execution, which also helps to simplify transportation, reduces the incurred costs and makes customization easier.

“To be able to customise the beams in situ makes it possible to adapt the characteristics of each of them to the structural needs at each point of construction. The possibility to recycle polymeric materials to produce the beams significantly decreases their carbon footprint,” concluded Miguel Sánchez, from the Department of Systems and Computer Science (DISCA) of the UPV.