Dec 1 2020

Plastic was invented in the late 19th century, and since then, it has transformed human lives. The advent of plastic paved the way to a robust, lightweight, and economical material, which significantly eased everyday life.

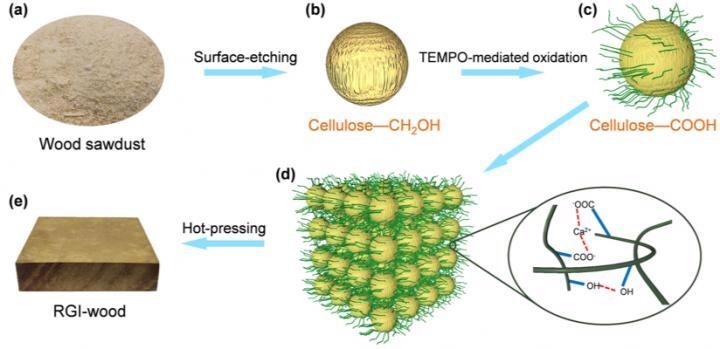

Schematic of the bottom-up approach to regenerate isotropic wood. Image Credit: Science China Press.

Schematic of the bottom-up approach to regenerate isotropic wood. Image Credit: Science China Press.

Petroleum-based plastics have a crucial role to play in human lives, but on the other hand, they contribute to a significantly increasing negative effect on the environment and human health. It is vague how long it will take for plastics to totally biodegrade into their basic molecules. The estimated range is from 450 years to never.

Plastics are difficult to decompose, and thus, sunlight and waves would have worn these non-degradable plastics into small bits, so-called microplastics. Those microplastics might float across the world’s oceans, absorbing toxins, waiting to be consumed by some unlucky oyster or fish, and eventually maybe the humans.

A potential alternative option to mitigate the dangers of plastic pollution is to develop sustainable materials for plastic substitute from all-green (i.e., 100% bio-based) standard building blocks.

Currently, a research team headed by Professor Shu-Hong Yu from the University of Science and Technology of China (USTC) has come up with a high-performance sustainable regenerated isotropic wood (RGI-wood), built from surface nanocrystallized wood particles (SNWP) by proficient bottom-up strategy with micro/nanoscale structure design.

Using surface nanocrystallization, numerous cellulose nanofibers expand from the surface of wood sawdust, and consequently, the properties of wood particles are greatly improved. The obtained RGI-wood surpasses the drawback of the anisotropic, unreliable mechanical properties and inflammability of natural wood, making it a robust competitor to petroleum-based plastics.

Large-scale production of large-sized RGI-wood can be realized, thus solving the issue of the rareness of large-sized natural wood. Furthermore, this bottom-up approach enables preparing a range of functional RGI-wood nanocomposites, which exhibit significant potential in varied applications.

Based on the powerful interaction between SNWP, high-performance RGI-wood can be prepared by the direct press. Using surface nanocrystallization of wood particles, RGI-wood beats the drawback of the anisotropic and unreliable mechanical properties of natural wood with a flexural modulus of ~10 GPa and isotropic flexural strength of ~170 MPa.

In contrast to natural wood, RGI-wood exhibits considerably higher flexural strength and modulus in both directions because of the large surface area of cellulose nanofibers and long-range hydrogen bond interaction between SNWP.

Furthermore, RGI-wood also displays greater fracture toughness, higher compressive strength, hardness, dimensional stability, impact resistance, and fire retardancy than natural wood. RGI-wood is an all-green biopolymer material and hence better than petroleum-based plastics in terms of mechanical properties, which enables RGI-wood to be a robust competitor to petroleum-based plastics in many application fields.

Also, since SNWP can serve as a great structural binder with the three-dimensional nano-network, this universal bottom-up approach holds the potential for building a series of bulk functional composites. For instance, the conductive smart RGI-wood can be made by blending SNWP with carbon nanotubes (CNTs) before pressing.

The conductive smart RGI-wood exhibits a lower percolation threshold and a lower exponent, signifying that CNTs can develop a better conductive network compared to that of polymer/CNTs composite.

Thanks to its high conductivity, the conductive smart RGI-wood displays superior electromagnetic shielding performance (more than 90 dB in the X-band), which matches the demands of shielding standards of precision electronic instruments.

Furthermore, the superior electrical conductivity of conductive smart RGI-wood also enables it to self-heat through Joule heat at low voltages. A low heating voltage can efficiently guarantee the safety of self-heating devices while minimizing energy consumption. Thus, the newly developed conductive smart RGI-wood can be used as electromagnetic shielding materials and self-heating wallboard for smart buildings.

In brief, the bottom-up approach with micro/nanoscale structure design overcomes the drawback of the anisotropic, inconsistent mechanical properties and sizes of natural wood by adding the surface nanocrystallization technique of biomass particles.

Moreover, the micro/nanoscale structure design approach can be used for other biomass (for example, rape straw, leaf, grass, etc.) to develop a series of all-green sustainable structural materials. Thanks to its enhanced mechanical properties compared to plastics, RGI-wood can become a robust competitor for petroleum-based plastics.

The RGI-wood and its nanocomposites also exhibit exceptional performance in different areas such as mechanical properties, smart materials, inflammability, and building materials.

This study was financially supported by the National Natural Science Foundation of China, Innovative Research Groups of the National Natural Science Foundation of China, Key Research Program of Frontier Sciences, Chinese Academy of Sciences, the National Basic Research Program of China, and the Users with Excellence and Scientific Research Grant of Hefei Science Center of Chinese Academy of Sciences.

Journal Reference:

Guan, Q.-F., et al. (2020) Regenerated isotropic wood. National Science Review. doi.org/10.1093/nsr/nwaa230.