May 28 2020

In the modern-day infrastructures, concrete is one of the strongest and most abundant building materials. However, it has a weakness—ice—which causes crumbling and spallation of concrete.

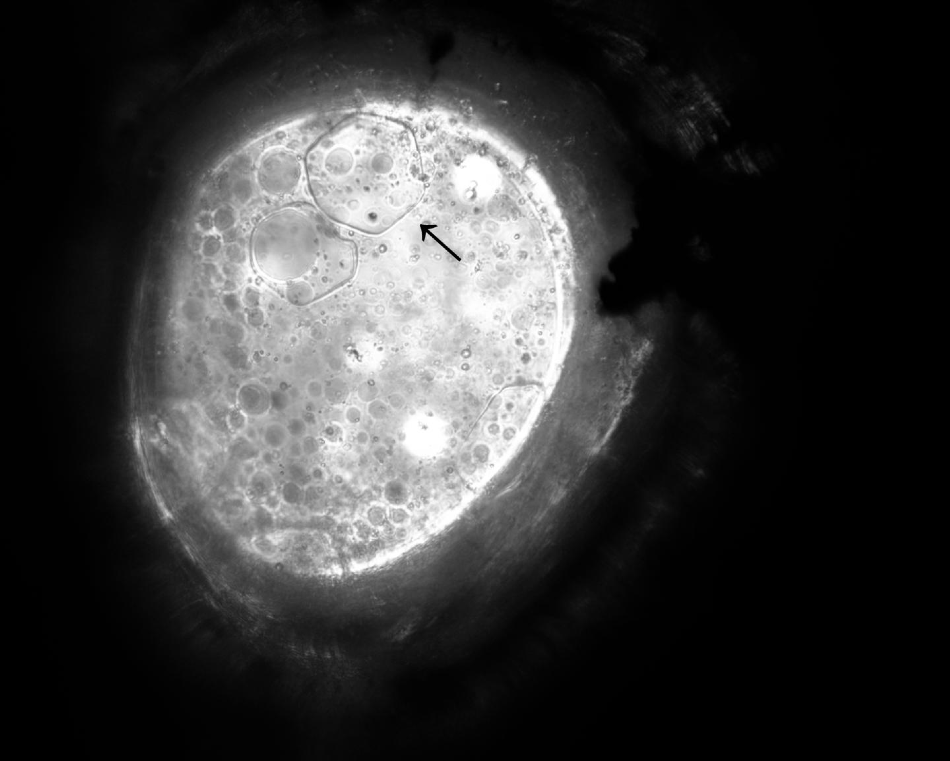

This image shows how ice crystals that bind with the polymer molecules experience dynamic ice shaping, changing from a sphere to a rounded hexagon, which the researchers call “lemon ice.” Image Credit: Living Materials Laboratory, University of Colorado Boulder.

This image shows how ice crystals that bind with the polymer molecules experience dynamic ice shaping, changing from a sphere to a rounded hexagon, which the researchers call “lemon ice.” Image Credit: Living Materials Laboratory, University of Colorado Boulder.

Taking cues from organisms that live in sub-zero conditions, scientists in Colorado are adding polymer molecules with anti-freezing properties into concrete.

The technique, which investigates whether the new concrete can prevent the damage due to freezing and thawing, has been reported in the Cell Reports Physical Science journal on May 27th, 2020.

Concrete is a porous material containing capillary pores that enable water to penetrate the material. In places that undergo wide temperature swings, concrete buildings and roads experience the so-called “freeze-thaw cycles.”

Within the material, the water expands and freezes, developing pressure as the ice crystals grow, ultimately popping the concrete’s surface off. The new polyethylene glycol-graft-polyvinyl alcohol (PEG-PVA) molecules that the scientists have discovered seem to keep the ice crystals small and inhibit them from combining into larger crystals.

We’re particularly excited because this represents a departure away from more than 70 years of conventional concrete technology. In our view, it’s a quantum leap in the right direction and opens the door for brand new admixture technologies.

Wil Srubar, Study Senior Author, Head of Living Materials Laboratory, University of Colorado Boulder

For more than 70 years, the main method to reduce freeze-thaw damage was to add small air bubbles that act as pressure release valves within the concrete, called air-entraining admixtures.

However, the addition of tiny air bubbles into the concrete not just reduces the material’s strength but also makes it more porous, which acts as a superhighway for further water and other damaging substances, such as salts, to enter. Rather than tackling the symptoms of ice expansions, the group decided to focus on the source: ice crystal growth.

The anti-freeze proteins identified in organisms that survive in sub-zero conditions attach to ice crystals to stop their growth that would otherwise be deadly to the organisms.

The researchers were motivated by the protein, and thus added polymer molecules, with properties similar to that of the protein, to the concrete mix. The molecules efficiently decreased the ice crystal’s size by 90%. Also, the new concrete mix resisted 300 freeze-thaw cycles and still retained its durability.

The new concrete has already cleared the industry-standard tests, but there are still doubts regarding the true long-term durability of the material in a real-world application and its economic practicability.

The further step for the researchers would be to improve their technique by determining new molecules that are more profitable and testing the adaptability of the molecule with various recipes of concrete. Srubar believes that concrete recipes can benefit from the new additive.

Making concrete is a lot like baking a cake. For the next 30 years, the world will be building a New York City every 35 days, which is astounding. What that means is that we’re going to be building a lot of buildings and roads, and we’re going to be using a lot of concrete.

Wil Srubar, Study Senior Author, Head of Living Materials Laboratory, University of Colorado Boulder

Srubar added, “Because it has significant impacts on the environment, the concrete that we do make really does have to be as sustainable as possible and as durable as it can be.”

This study was financially supported by the US National Science Foundation and the National Highway’s Cooperative Research Program.

Journal Reference:

Frazier, S D., et al. (2020) Inhibiting Freeze-Thaw Damage in Cement Paste and Concrete by Mimicking Nature’s Antifreeze. Cell Reports Physical Science. doi.org/10.1016/j.xcrp.2020.100060.