Apr 23 2020

The most extensively used building material across the globe is concrete. Therefore, it is being developed constantly to meet the requirements of the contemporary world.

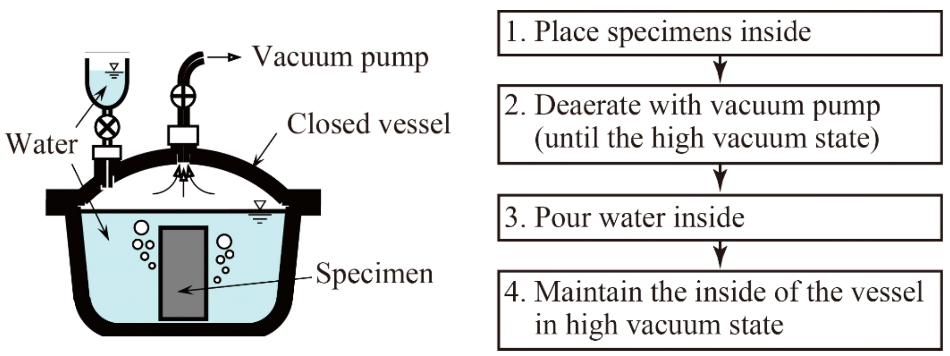

Outline of degassing and water absorption treatment. The PFC specimens are then placed in a closed vessel that was depressurized using a vacuum pump, and water introduced from the outer surface to the inside. Image Credit: Kanazawa University.

Outline of degassing and water absorption treatment. The PFC specimens are then placed in a closed vessel that was depressurized using a vacuum pump, and water introduced from the outer surface to the inside. Image Credit: Kanazawa University.

The measures taken to enhance concrete strength have resulted in porosity-free concrete (PFC). It is the hardest concrete that has been tested to date. Few of the fundamental properties of PFC have been explored earlier. Currently, a group of researchers from Kanazawa University has investigated the response of this novel material to impact.

The results of the study have been published in the International Journal of Civil Engineering.

The ultra-high-strength concrete provides considerable benefits such as decreasing the weight of large structures and safeguarding them against accidental impacts and natural disasters. PFC is an ultra-high-strength concrete, the properties of which can be improved even more by combining steel fibers.

The preparation method for PFC results in a very few voids in the final material, which offers its high strength—400 MPa can be exerted on PFC before it breaks, in comparison with 20–30 MPa for normal concrete.

Some of the fundamental material properties of steel fiber-reinforced PFC have been reported earlier. Currently, the scientists have assessed the impact response of a wide array of PFC preparations with various section heights and steel fiber contents.

The continued development of building materials is particularly important in areas where frequent natural disasters threaten the integrity of structures.

Yusuke Kurihashi, Study Lead Author, Kanazawa University

Kurihashi continued, “We carried out impact tests on a variety of steel fiber-reinforced PFC samples to determine their reactions, and in so doing, accelerate the widespread application of PFC in building projects. Our testing is designed to simulate responses to events such as rock falls, blasts and flying objects.”

Two primary findings were made by the scientists. Initially, the researchers observed that when the content of steel fiber was increased from 1% to 2%, the damage caused by the impact was reduced by 30% to 50%. It is predicted that this substantial enhancement in performance will apply to future material design decisions.

Moreover, the researchers demonstrated that it is feasible to estimate the behavior of the samples with around 80% precision by comparing calculated values with the measured values. This will help streamline the development processes.

We hope that PFC will contribute to enhanced building safety in the future. Although additional experimental work and statistical processing is required to fully translate PFC into widespread practical applications, our findings make a significant contribution to understanding PFC’s role in improving the safety of many large structures including high-rise buildings, bridges and roads.

Yusuke Kurihashi, Study Lead Author, Kanazawa University