Apr 10 2020

At the Toyohashi University of Technology (TUT), scientists from the Structural Engineering Laboratory of the Department of Architecture and Civil Engineering have proposed a new idea for making steel in crucial building structures stronger.

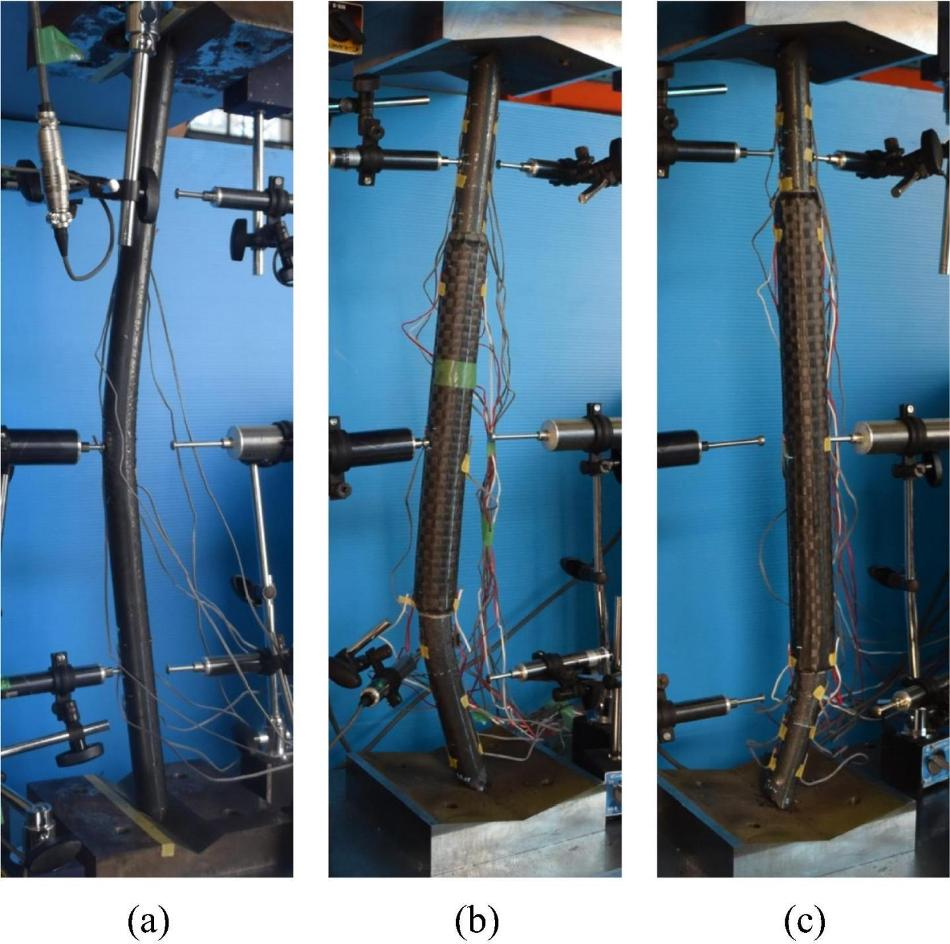

A failure due to the classical global buckling of the both-end-pinned column is experienced by the control unstrengthened specimen, (a). Compared with the shape of the control specimens, the deformed shape of all CFRP-strengthened specimens is quite different, and it enables an effective increase in the maximum compressive loading. Image Credit: © Toyohashi University of Technology.

A failure due to the classical global buckling of the both-end-pinned column is experienced by the control unstrengthened specimen, (a). Compared with the shape of the control specimens, the deformed shape of all CFRP-strengthened specimens is quite different, and it enables an effective increase in the maximum compressive loading. Image Credit: © Toyohashi University of Technology.

The new concept involves using bond-free carbon fiber reinforced plastic (CFRP) laminates to improve the buckling performance of structural steel elements.

Treatment of steel surface before CFRP application is not needed in this technique because the CFRP is not attached to the surface, which enhances structural strength via its flexural rigidity.

The results of the study were published recently in the Construction and Building Materials journal.

CFRP has been successfully used in the field of civil engineering for the reinforcement of concrete, and at present, it has been applied for strengthening steel members rather than the traditional steel plates in use. CFRP is sought-after as it provides many advantages like high strength-to-weight ratio, lightweight, and outstanding corrosion and fatigue resistance.

Until now, the focus of research and development for strengthening steel through CFRP has been mainly on bonding methods that involve attaching CFRP to steel surfaces with the help of an adhesive. Bonded strengthening has several drawbacks as time-consuming and difficult surface treatments are needed before CFRP installation.

Furthermore, the performance of bonding strength between CFRP and steel—the main aspect of this strengthening method—can also decline considerably because of environmental exposure throughout the service life. Substitution of this technique with an alternative bonded-CFRP method is not a proper solution since it is unlikely to be economical.

The researchers developed their technique for strengthening steel with CFRP, without attaching the CFRP to the steel surface. This technique has been demonstrated to retard buckling and enhance the compression ability of steel bars, where the capacity gain is influenced by the number of carbon fiber layers used.

As an alternative to the steel strengthening method using CFRP which is bonded to the steel surface, we developed this unbonded-CFRP method."

Fengky Satria Yoresta, Study Primary Author, Toyohashi University of Technology

Yoresta added, “The major advantages of this method are that it is easier and less time-consuming to implement, especially when it is applied to the existing elements of building structures. No more troublesome steel surface treatments are needed, such as sandblasting, grit blasting, or hand grinding, and this leads to significant cost savings.”

Nearly all previous studies used adhesively-bonded joints to strengthen steel members with CFRP. This method is quite complex because appropriate steel surface treatments are required before the application of the CFRP to obtain an acceptable bond between the CFRP and the steel surface. The surface treatment conditions also affect bonding strengths."

Yukihiro Matsumoto, Associate Professor, Toyohashi University of Technology

Matsumoto is also the leader of the research team.

Matsumoto continued, “Moreover, we cannot perfectly estimate the effects of environmental exposure during the service life on the bonding performance between the CFRP and the steel. As such, we sought to improve on conventional methods by developing our own bond-free strengthening method.”

The unbonded strengthening method is useful, easy to apply, and manageable. However, our method does not transfer stress smoothly, so an appropriate mechanical model needed to be established. Consequently, we performed mechanical simulations and experiments to demonstrate this."

Yukihiro Matsumoto, Associate Professor, Toyohashi University of Technology

From the study results, the researchers believe that the bond-free CFRP technique can be employed not just in civil engineering but also in alternative fields such as marine, automotive, and aerospace sectors. This latest technique is anticipated to be used to quickly generate high-quality and novel products.