Aug 5 2019

A group of engineers headed by Rutgers reports that special permeable concrete pavement can help decrease the “urban heat island effect” due to which cities turn torrid in the summer.

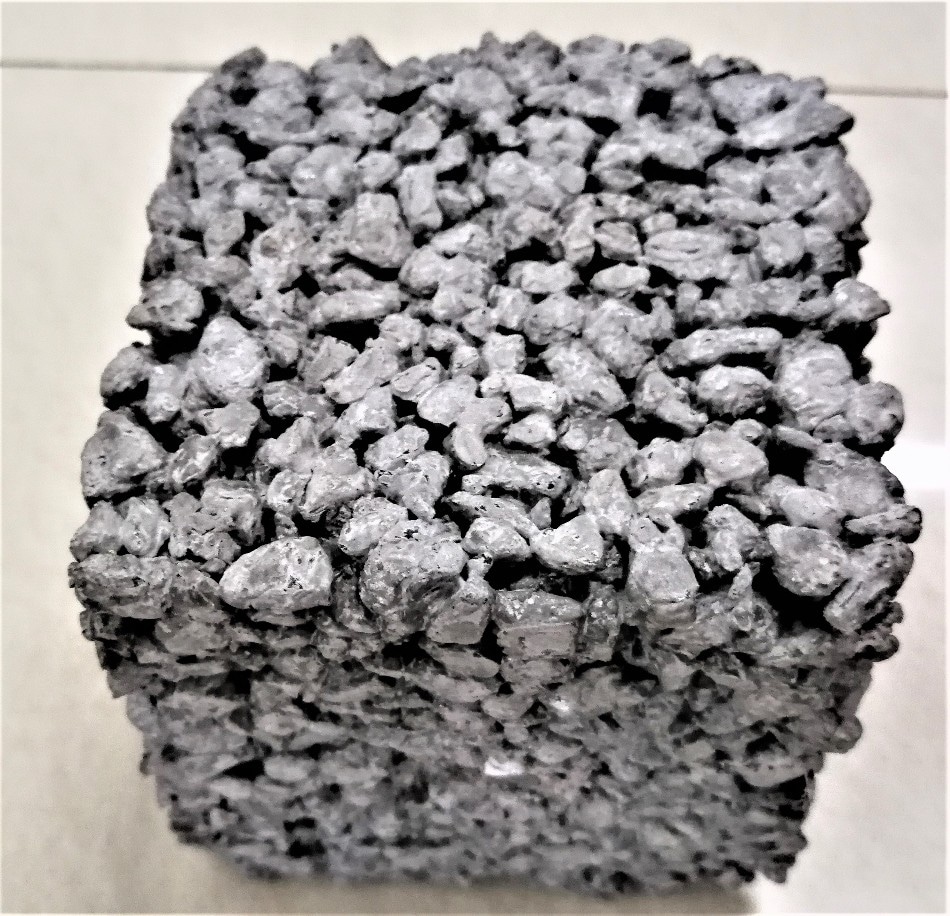

A permeable concrete specimen. (Image credit: Hao Wang/Rutgers University-New Brunswick)

A permeable concrete specimen. (Image credit: Hao Wang/Rutgers University-New Brunswick)

Their research has been published in the Journal of Cleaner Production. Impermeable pavement composed of asphalt or concrete covers more than 30% of most urban areas and can reach beyond 140 ○F in the summertime. It heats up the air, causing human health risks and surface runoff that endangers aquatic life.

Average air temperatures in cities with a population of 1 million or more can be 1.8–5.4 ○F higher than less densely populated areas. The difference can reach up to 22 ○F at night.

The U.S. Environmental Protection Agency reports that the heat can increase peak demand for energy in the summertime, air-conditioning costs, water pollution, air pollution, and greenhouse gas emissions, as well as heat-related illness and deaths.

The engineering group at Rutgers created designs for permeable concrete that is highly effective in handling the heat. Permeable pavement consists of large connected pores, permitting water to percolate and minimizing pavement temperature.

Furthermore, water in pores will evaporate, thus minimizing pavement surface temperature. In addition, permeable concrete pavement reflects heat better when compared to asphalt pavement.

The research discovered that permeable concrete pavement emits slightly more heat on sunny days than traditional concrete pavement, but 25%–30% less heat on days following rainfall. The engineers enhanced the permeable concrete’s design with high thermal conductivity—implying that it can transfer heat to the ground more rapidly—further minimizing heat output by 2.5%–5.2%.

Highly efficient permeable concrete pavement can be a valuable, cost-effective solution in cities to mitigate the urban heat island effect while benefitting stormwater management and improving water quality.

Hao Wang, Study Corresponding Author and Associate Professor, Department of Civil and Environmental Engineering, School of Engineering, Rutgers University–New Brunswick

He is also an affiliated researcher at the Center for Advanced Infrastructure and Transportation.

By including industry byproducts and waste into permeable concrete, its economic and environmental advantages can be increased. In another research reported in the Journal of Cleaner Production, Wang’s group developed permeable concrete with fly ash and steel slag to minimize the energy consumption, costs, and greenhouse gas emissions associated with raw materials.

Earlier, permeable pavement has been employed as green infrastructure to decrease stormwater runoff and flooding risk in urban regions. At present, permeable concrete is principally employed in regions with slight traffic, for example, parking lots, sidewalks, and rest areas.

The group led by Rutgers is examining how to strengthen permeable concrete and make it more durable in order to be used in urban streets.

Jiaqi Chen, a former postdoctoral researcher at Rutgers, and Xiaodan Chen, a Rutgers doctoral student, are the lead authors of the two studies. Co-authors of this research are Professor Husam Najm and engineering researcher John Hencken at Rutgers and collaborators at the New Jersey Department of Transportation and Central South University in China.