Some of the world’s most famous historical landmarks took thousands of workers and hundreds of years of backbreaking labour to construct. But with innovations in construction technology and today’s building techniques, how long would they take to build now, and how would it be done?

Technological innovation is integral to what E.ON does so with the help of specialist architect, Matt Spinks, Director of Johnson Design Partnership Ltd, E.ON reveals how modern technology and sustainable power would impact the construction time and the workforce needed to build yesterday’s landmarks, today.

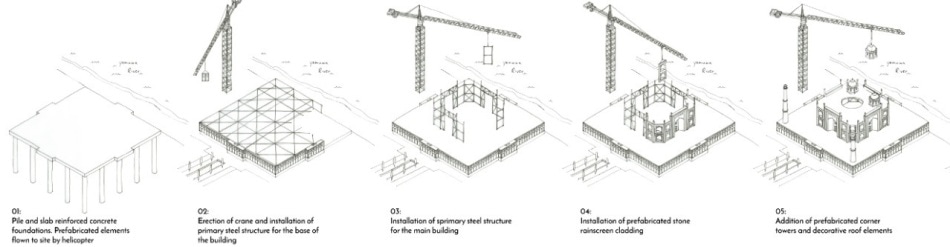

Highly detailed architectural blueprints show each stage of the modern-day construction process for the following 10 landmarks:

- The Great Wall of China

- Petra in Jordan

- Stonehenge in Wiltshire

- Angkor Wat in Cambodia

- Machu Picchu in Peru

- Chichén Itzá in Mexico

- The Parthenon in Greece

- Rome’s Colosseum

- Taj Mahal in India

- Pyramids of Giza in Egypt

The Great Wall of China would have originally taken more than 2,000 years (and an astonishing 1.5 million people) to complete by hand, using basic rope and wooden basket pulleys to fit the individual bricks and stones together. Today, it would take as little as 15 years to complete and require a workforce of just 5,000. Matt Spinks attributes the reduced construction time to the individual components being mass-produced offsite to create a kit of parts that could be easily pieced together, then transported into position by helicopters.

The modern-day construction technology that would be used to reduce Chichén Itzá’s build duration from hundreds of years to just five, consists of innovative solutions. Helicopters and laser cutting would form a large part of the initial construction, and once complete, the building could be cooled and heated using sustainable technology like air source heat pumps and be lit with solar powered LEDs.

Stonehenge is one of the world's great mysteries and is thought to have taken over 1,500 years to build. But with modern-day construction methods and crane operated assembly, experts at Johnson Design Partnership Ltd estimate the build time would drop from 1,500 years to one. Utilising technologies such as 3D printing to recreate the stones in an alternative material would drastically decrease the amount of people needed to source, cut and transport the stone from Wales to build the famous English Heritage site today.