Jun 21 2018

A composite binder composed mainly of fly ash, a byproduct of coal-fired power plants, has been developed by Rice University engineers to possibly serve as a replacement for Portland cement in concrete.

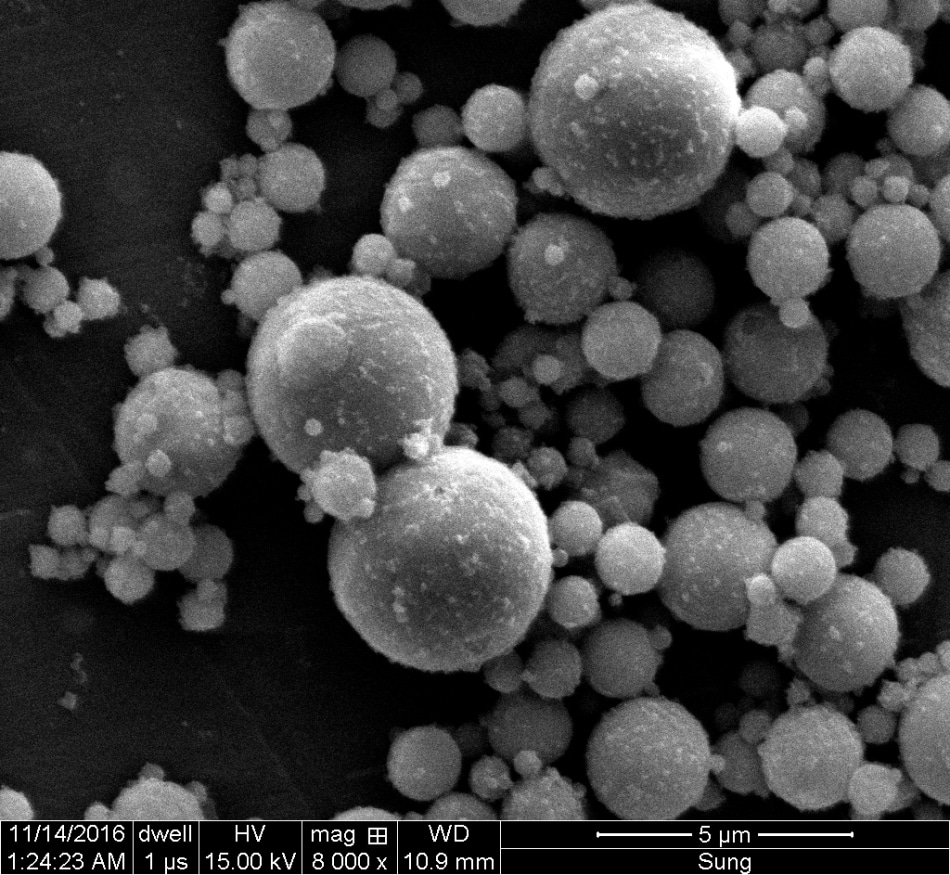

A scanning electron microscope image shows spherical particles in type C fly ash used by Rice University engineers to make cementless binder for concrete. (Courtesy of the Multiscale Materials Laboratory)

A scanning electron microscope image shows spherical particles in type C fly ash used by Rice University engineers to make cementless binder for concrete. (Courtesy of the Multiscale Materials Laboratory)

The material is both cementless and eco-friendly, according to Rice materials scientist Rouzbeh Shahsavari, who created it along with graduate student Sung Hoon Hwang.

Fly ash binder does not necessitate the high-temperature processing of Portland cement; however, tests revealed it possesses the same compressive strength after seven days of curing. It needs just a small fraction of the sodium-based activation chemicals used to harden Portland cement.

The results have been published in the Journal of the American Ceramic Society.

Globally, over 20 billion tons of concrete are manufactured per year in a manufacturing process that adds 5 to 10% of carbon dioxide to global emissions, surpassed only by energy and transportation as the largest creators of the greenhouse gas.

Manufacturers frequently use a small quantity of silicon- and aluminum-rich fly ash as an addition to Portland cement in concrete. “The industry typically mixes 5 to 20 percent fly ash into cement to make it green, but a significant portion of the mix is still cement,” said Shahsavari, an assistant professor of civil and environmental engineering and of materials science and nanoengineering.

Earlier attempts to completely substitute Portland cement with a fly ash compound required large quantities of costly sodium-based activators that negate the environmental advantages, he said. “And in the end, it was more expensive than cement,” he said.

The scientists used the Taguchi analysis, a statistical technique formulated to narrow the large phase space - all the likely states - of a chemical composition, followed by computational optimization to find the ideal mixing approaches.

This significantly enhanced the mechanical and structural qualities of the synthesized composites, Shahsavari explained, and led to an ideal balance of calcium-rich fly ash, calcium oxide, and nanosilica with less than 5% of a sodium-based activator.

A majority of past works focused on so-called type F fly ash, which is derived from burning anthracite or bituminous coals in power plants and has low calcium content. But globally, there are significant sources of lower grade coal such as lignite or sub-bituminous coals. Burning them results in high-calcium, or type C, fly ash, which has been more difficult to activate.

Our work provides a viable path for efficient and cost-effective activation of this type of high-calcium fly ash, paving the path for the environmentally responsible manufacture of concrete. Future work will assess such properties as long-term behavior, shrinkage, and durability.

Shahsavari

Shahsavari proposed the same approach could be used to convert other industrial waste, such as rice hulls and blast furnace slag, into eco-friendly cementitious materials without utilizing cement.