Jul 20 2017

Scientists from University of Leeds have used the principles of light to find a new way to measure the strength of modern types of concrete – providing the construction industry a better way to understand where the material could fracture.

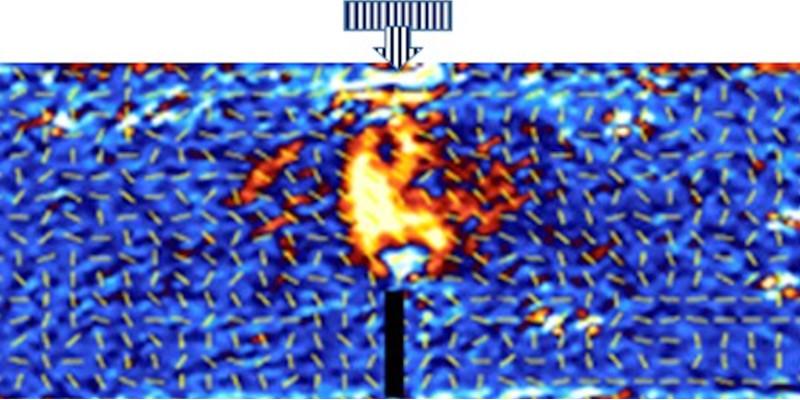

A picture from a photonic camera showing how using the coating can create a candle-like 'flame' highlighting shear stress distribution in a sample concrete beam. Credit: University of Leeds

A picture from a photonic camera showing how using the coating can create a candle-like 'flame' highlighting shear stress distribution in a sample concrete beam. Credit: University of Leeds

Their method was based on using a complex light-refracting coating, developed to display stress positions, to the concrete beam samples’ surface.

The epoxy coating is ‘birefringent’ and it has the ability to split light waves in various directions in relation to the level of stress produced in those directions, and then reflects it back to a photonic camera.

The camera then takes a picture revealing where the stress levels are very high before fractures or cracks occur.

The coating is not new, but it is the first time the research project has used the coating to assess the toughness and measure shear stress of concrete against fractures.

There are other methods to measure stress and strain levels in the engineering sector, but we do not believe any of them can measure shear strain directly with high precision, which is most relevant to assess the failure strength of materials. The photonic method we developed can directly measure sheer strain, even on opaque materials. Until now, photonic and optical methods of measurement have only been associated with transparent materials.

Dr Joseph Antony, the School of Chemical and Process Engineering, who led the study in collaboration with Researchers at the University of Qatar

The results using the new method were favorably compared with standard methods of stress testing, which have depended on combined experimental and numerical or analytical approaches.

New materials

The rise of composite concretes, which are extensively used in the construction industry, prompted the Researchers to look for new ways to study the strength of the material.

Traditionally, concrete has been made from sand, gravel and cement, but in recent decades, it has changed significantly.

Now, numerous waste products such as plastic pellets have been used to reduce the levels of natural materials and to recycle waste products.

Our study was aimed at developing a method by which plastic or polymer waste materials, in this case from Qatar, could be used as valuable ingredients in developing new engineering products. By working with industries which recycle the waste products into micron sized particles, we had direct insight into how they are used, meaning our study could be much more informed by industry requirements.

Dr Joseph Antony, the School of Chemical and Process Engineering, who led the study in collaboration with Researchers at the University of Qatar

Finding a new method to show the construction industry the precise toughness of the new forms of composite concrete meant that there could be more dependence on their use as a building material.

Dr Antony described that compared to traditional ingredients, concrete made with waste plastic products had demonstrated superior qualities, but his team wanted to make sure that it could maintain service loads without fracturing.

We believe this new photonic or optical approach to fracture testing could be applied not only to develop sustainable manufacturing using materials that would otherwise be discarded as waste, but also in other diverse engineering designs including mechanical, civil, materials, electronics and chemical engineering applications.

Dr Joseph Antony, the School of Chemical and Process Engineering, who led the study in collaboration with Researchers at the University of Qatar

The research was funded by the Qatar National Research Fund, and is published in Scientific Reports.