Dec 7 2015

Building burglary-resistent doors with thermal insulation is a challenge for manufacturers. Their complex structure provides holes for the flow of air. With scientific simulation methods, Fraunhofer researchers have designed an insulating construction on the computer – without expensive prototypes having to be built.

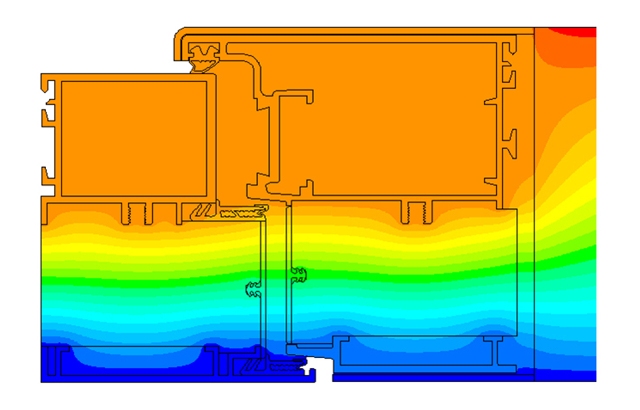

Cross-section of burglary-resistent external doors: Using scientific simulation methods, Fraunhofer researchers have identified the exact points where heat escapes through the aluminum frame (dark color). © Fraunhofer ITWM

Cross-section of burglary-resistent external doors: Using scientific simulation methods, Fraunhofer researchers have identified the exact points where heat escapes through the aluminum frame (dark color). © Fraunhofer ITWM

Small and mid-sized companies usually do not have a research department. The expertise of scientists can also create added value for them, though. This is shown by the example of a manufacturer of burglary-resistent house doors from Rhineland-Palatinate in Germany: simulation methods and software tools of the Fraunhofer Institute for Industrial Mathematics ITWM in Kaiserslautern have been helping to construct these burglary-resistent doors such that they are now eligible for a grant from the Kreditanstalt für Wiederaufbau (KfW- Credit Institute for Rebuilding). The new frame construction provides the entire door with an heat transfer coefficient (HTC) of 0.49 W/m²K. In the process, its burglary-resistent properties remain unchanged.

“This is a very low value for burglary-resistent doors, considering their complex structure,” says Dr. Matthias Kabel from the Department Flow and Material Simulation at ITWM. “Previously, the frame constructions had a value of 2.84 W/m²K. Now, the HTC of the models from the company catalog are less than 1.3 W/m²K. All doors are therefore eligible for funding,” says Dr. Kabel. The HTC is a measure of the thermal transmittance of a gas through a solid body. It is expressed in watts per square meter and Kelvin (W/m²K). “We have demonstrated through the project that with the help of complex simulation methods and software tools, we can optimize even our everyday objects – with direct added value for the customer,” says Dr. Kabel.

No expensive prototypes are needed

The company manufactures burglary-resistent doors and door frames made of aluminum. The problem: aluminum is particularly good at conducting heat. Cold penetrates into the house and interior heat escapes to the outside. “Not an ideal situation for the energy efficiency of the house,” says Dr. Kabel. The ITWM researchers compared and tested the design proposals by predicting all the essential functional properties using precise numerical calculation methods. “With the help of computer simulations, we have been able to look at a large number of possible variants and to design the various materials in the area of the door leaf and the frame profile to the exact millimeter,” says Dr. Kabel. The manufacturer did not have to build its own prototypes for the individual variants. As a result, it saved time and costs. “With our tools, we were able to quickly pair up information about the door structure and heat transfer with the requirements of the DIN standard for thermal insulation of windows, doors and shutters. This resulted in proposals for optimal design plans of various door models for the company,” says Dr. Kabel.

In the first step, the scientists showed that they can simulate the real measurements of heat transfer on the computer precisely. “This helped the customer to become more confident in the process. The company does not have a research department and worked intensively with us on product development,” says Dr. Kabel. “Without the simulation, the manufacturer would only have had the mean value of the heat loss of the frame. With the help of the computer-assisted illustration, it was possible to determine exactly which part of the frame was responsible for which portion of the heat loss. We made specific proposals about how the design of the frame could be thermotechnically optimised.” The researchers adapted their simulation software to the requirements of the problem regarding the doors: among other things, this included selecting the right material parameters, digitally and accurately portraying the physical effects of heat transport in doors, as well as considering the corresponding DIN norm in the simulation software.

The thermal insulation of houses is a key component of energy transmission and is promoted in Germany. The federal government of Germany wants to greatly reduce energy consumption in residential buildings by the year 2050. Through the KfW, it is also promoting the installation of thermally-insulated interior and exterior doors. However, only if an HTC of less than 1.3 W/m²K can be verified.