Feb 12 2015

Mitsubishi Electric Corporation has developed three-dimensional (3-D) model reconstruction technology to reconstruct accurate 3-D models of large indoor areas, using a tablet equipped with a 3-D sensor, for efficient on-site planning of renovation work. The company plans to commercialize a 3-D modeling tool for offices, factory interiors and elevator shafts in 2018.

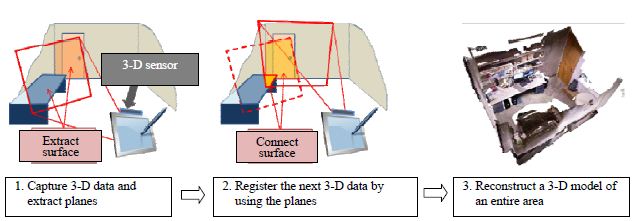

The new technology extracts planes automatically from 3-D point-cloud data captured using a tablet equipped with a 3-D sensor. The technology registers a sequence of 3-D data by automatically finding and associating identical planes and points in different frames to reconstruct an accurate 3-D model of an entire area. A software processes the 3-D data in real time at a speed of four frames per second.

The 3-D models can be used, for example, to measure distances between specific locations or avoid collisions when moving an object, enabling highly efficient planning.

Efficient and accurate 3-D modeling is very useful because 2-D floor plans and 3-D models of existing constructions—such as elevator shafts, pipes and wires in factories, and details of building interiors—often are not available, or are not accurate. Conventional systems for reconstructing 3-D models require extensive time to take measurements, or are not suitable for large areas.