The recent loft-and-roof model that was field-tested at the Department of Energy's Oak Ridge National Laboratory is proficient in keeping building interiors cool during summer and counters heat loss during winter, an all-season advantage rarely found in conventional loft-and-roof architecture.

ORNL's new roof system

ORNL's new roof system

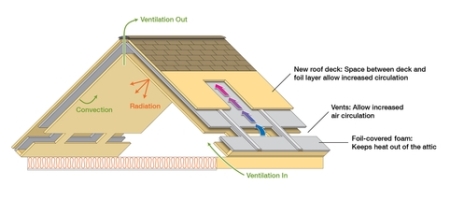

The system provides optimization through controls for convection, insulation and radiation, inclusive of a passive ventilation setup that draws air from the lower portion of the loft into an inclined air space on top of the roof.

The new roof model can be retrofitted with most roofing products. The main feature of the roof model is a covered foiled polystyrene insulation that fits over and between rafters in new constructions or in existing shingle roofs. The shingles do not have to be moved. This saves plenty of money and effort. According to ORNL computer replicas, badly sealed HVAC ducts leak treated air into a loft, which causes expenses of $100-300 annually. Some homeowners spend $8000 to seal the loft with spray foam, which can save $460 or more annually. At lesser initial cost and same payback years, homeowners can retrofit their lofts with the new model for around $2000, thus saving $200 annually. Keeping the future in view, Bill Miller of DOE's Building Envelope Group along with his co-workers are trying to find models with lesser initial fixing costs and better economy on the whole. He mentions that in the new model heat that may have entered the interior of a house will be directed upward and out. Also, since the passive ventilation setup has no moving parts, it should work quite well.

Source: http://www.ornl.gov/