The construction industry is responsible for 11% of all anthropogenic carbon dioxide (CO2) emissions worldwide, and cement manufacturing is to blame for the bulk of this impact. Prometheus Materials, a startup commercializing University of Colorado Boulder research, recently began production of a coral-inspired organic biocomposite concrete alternative that could eventually become carbon-negative.

Image Credit: Lea Rae/Shutterstock.com

Concrete’s Environmental Impact

Cement – the main binding component for concrete, bricks, and mortar – produces about 7% of the world’s CO2 emissions. Ranked in a list of the world’s worst countries for carbon emissions, cement manufacturing would come third.

One-tenth of these emissions are from powering grinders and blenders to crush limestone into clinker, three-tenths are from burning fuel to bring the clinker up to extremely high temperatures, and the remaining six-tenths are emitted during the calcination process that this causes.

Cement manufacturing also creates sulfur oxide and nitrogen oxide emissions, which can lead to smog. Fine particulate matter – more than all the trucks in the world – is also spewed from cement plants, severely harming local air quality.

But the world’s population is still growing. New construction is needed both to accommodate more people and to deal with challenges such as new industries, climate change, migration, and unequal economic development.

Microsoft-Backed Startup with Innovative Response to Concrete Challenge

Microsoft, for example, plans to build at least 50 new data centers every year for the foreseeable future. But the company needs to find ways to undertake these projects while steering operations toward net carbon negativity. Recently, Microsoft invested in a startup that may have the solution.

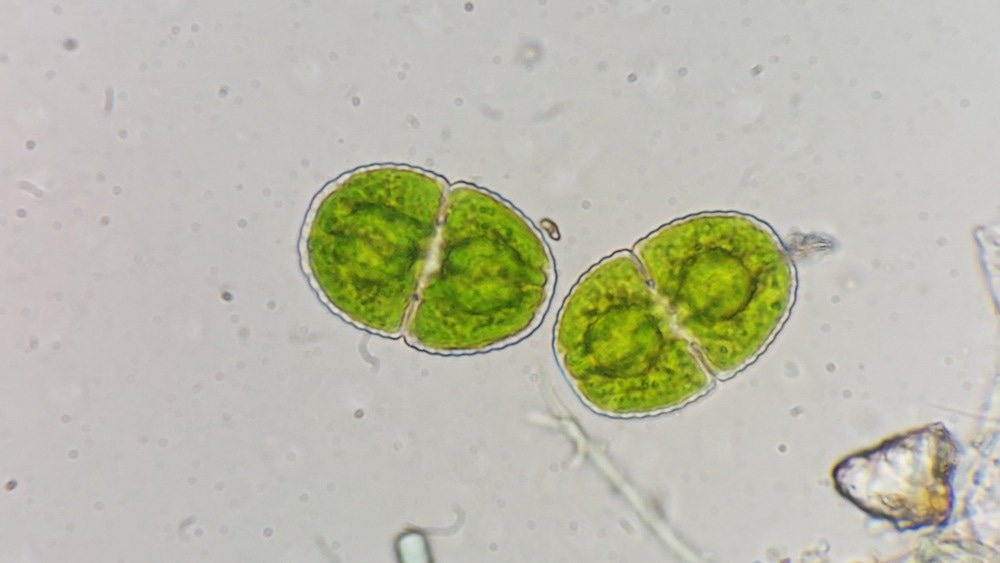

Prometheus Materials came about from biotechnology and engineering research carried out at the University of Colorado Boulder since 2016. The researchers used microalgae as a living building material, creating a Portland cement alternative. Prometheus Materials was founded in 2021 and began commercial production of bio-concrete materials for the construction industry in late 2022.

Previously, researchers involved had experimented with Synechococcus, a cyanobacteria type that is abundant in oceans and with potential application as an exponentially regenerative building material. Limestone crystals made from E. coli bacteria were another avenue of research, and the team expects to find more applications for engineered bacteria in the future.

How to Make an Algae-Based Concrete Alternative

Such materials could be carbon negative, removing CO2 from the atmosphere instead of adding them. This is because algae, for example, naturally extract CO2 from the atmosphere through photosynthesis while growing.

Prometheus Materials takes microalgae found on ponds and grows it in bioreactor tanks. There, they can add air, seawater, and LED light. The algae then create a cement-like substance that can act as the binding agent in concrete, instead of Portland cement.

Image Credit: Ekky Ilham/Shutterstock.com

The company is currently awaiting patents for this photosynthetic bio-cementation process. It uses biomineralizing cyanobacteria which are non-toxic and can grow with just sunlight, seawater, and CO2 from the atmosphere.

The method is inspired by the biological process that creates hard coral reefs. On the company’s website, CTO and co-founder Wil Shrubar writes: “Coral reefs, shells, and even the limestone we use to produce cement today show us that nature has already figured out how to bind minerals together in a strong, clever, and efficient way.”

This biomimetic approach was important for developing a more environmentally friendly building material. The nature-inspired process can form part of a net-zero embodied emissions process (including biogenic carbon emissions).

Prometheus’s Biobricks

This algae concrete can be produced in under a day in Prometheus Materials’ facility. Concrete masonry units (CMUs) manufactured here conform to materials standards, and the company is planning to roll out a varied ready-mixed product line over its first year in production.

The blocks have high compressive strength, approximately 2000 psi, making them suitable for structural as well as non-structural applications. The company says its products will become even stronger as a result of future development.

The final brick currently contains about a tenth of the embodied CO2 of traditional concrete blocks, according to the company. This will become even less in the future, as solar panels are currently being installed. Within three years, it predicts that it will be able to produce a concrete alternative for net negative CO2 emissions.

Going Into Production

Prometheus’s solution has good potential for scalability, according to investors SOM, the architecture firm behind the Burj Khalifa. While initial production is taking place in a Colorado facility, Prometheus Materials intends to supply a dried, lightweight biocement product that can be used in place of cement to make algae-based bricks without specialized equipment.

Once into full-scale production, the company has previously said it would produce tens of thousands of blocks daily, targeting a price point that avoids the “green premium” to reach a mainstream market.

Could Bio Building Materials Be the Basis for a Future Construction Industry?

Biological building materials may be the solution for the construction industry’s catastrophic environmental impact. If we can build out of materials that grow, ingesting CO2 through photosynthesis, then our buildings can act as carbon sinks and actively reduce the amount of CO2 in the atmosphere.

Grass, thatch, leaves, and wood have been used as building materials for millennia. However, these biological materials are not scalable enough to meet the demands of a huge, growing, and still developing human population.

But new bio-based products like Prometheus Materials’s algae-based concrete are starting to enter the market. Like much environmental technology, many of these products have faced challenges in scaling up to meet demand. Prometheus Materials’s future depends on solving the challenge of scale.

More from AZoBuild: Carbon-Negative Building Systems to Reduce Emissions

References and Further Reading

Blakemore, E. (2020). Self-growing bricks, self-healing building materials from bacteria may be the future of construction industry. [Online] Washington Post. Available at: https://www.washingtonpost.com/science/self-growing-bricks-self-healing-building-materials-from-bacteria-may-be-the-future-of-construction-industry/2020/04/10/c2fa620e-79e9-11ea-b6ff-597f170df8f8_story.html (Accessed on 16 January 2023).

Frequently Asked Questions. [Online] Prometheus Materials. Available at: https://prometheusmaterials.com/faq/ (Accessed on 16 January 2023).

Heveran, C.M., et al (2019). Biomineralization and Successive Regeneration of Engineered Living Building Materials. Matter. doi.org/10.1016/j.matt.2019.11.016.

Miller, S., and S.C. Moore (2020). Climate and health damages from global concrete production. Nature Climate Change. doi.org/10.1038/s41558-020-0733-0.

Nugent, C. (2022). Follow the Algae Brick Road to Plant-Based Buildings. [Online] Time. Available at: https://time.com/6192603/algae-plant-buildings-carbon/ (Accessed on 16 January 2023).

Peters, A. (2021). The data center of the future is made of algae bricks and runs on hydrogen fuel cells. [Online] Fast Company. Available at: https://www.fastcompany.com/90689714/the-data-center-of-the-future-is-made-of-algae-bricks-and-runs-on-hydrogen-fuel-cells (Accessed on 16 January 2023).

Schlanger, Z. (2020). Construction Causes Major Pollution. Here's How We Can Build Better. [Online] Huffington Post. Available at: https://www.huffingtonpost.co.uk/entry/construction-major-pollution-how-we-build-better_n_5ea3464bc5b6f9639814c009 (Accessed on 16 January 2023).

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.