Could the cities of the future be built with materials that do not produce carbon dioxide emissions during their manufacture? This is the focus of recently published research into producing environmentally-friendly cement using a surprising natural resource – algae.

Image Credit: Chokniti-Studio/Shutterstock.com

The Construction Sector and Climate Change

Construction is a key industrial sector, providing domestic dwellings, commercial buildings, and infrastructure for a rapidly urbanizing and industrializing society

Cement is the most widely-used construction material in the world, and is predicted to remain so for the foreseeable future. However, the use of this material comes with a massive cost to the environment, with cement manufacturing producing around 8% of global carbon dioxide emissions.

These carbon emissions have been intrinsically linked to climate change, driving global temperature rises and unprecedented damage to the natural world. Climate change has been linked to the acidification of water bodies, loss of sea ice, accelerating biodiversity loss, and increasing instances of extreme weather events in recent years.

Decarbonizing the Industry

In order to meet the aims of the carbon-free economy and international commitments to attain net-zero emissions by 2050, there is an urgent need for the construction industry to rapidly decarbonize. Several strategies have been explored in the sector in recent decades, including using alternative materials, reusing and valorizing waste streams, and developing more sustainable technologies and working practices.

Decarbonizing the industry and improving the sustainability of future construction projects requires large investments in new and innovative technologies. Consequently, this requires immense capital investment and the will of multiple actors within the construction ecosystem, from small companies, researchers, and consumers to large multinational corporations and governments.

The use of renewable energy can significantly reduce the carbon emissions produced during cement production, as well as the implementation of carbon capture and storage technologies on an industrial scale. Aside from these strategies, implementing alternative, carbon emission-free technologies for the manufacture of key materials such as cement provides significant opportunities for decarbonization.

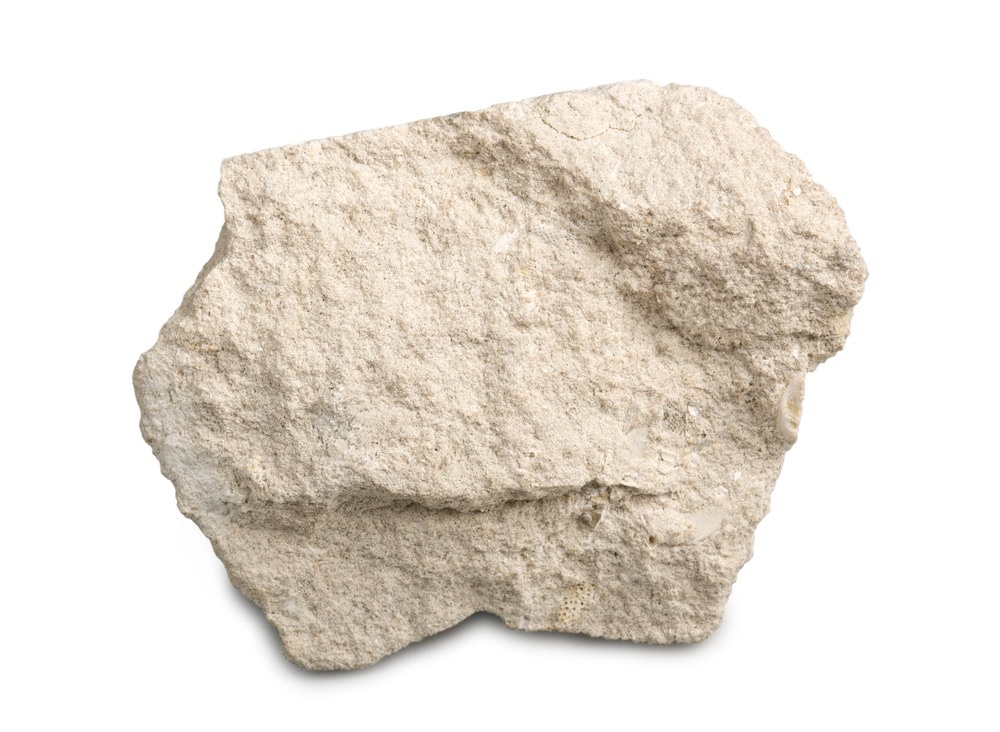

Emission-Free Limestone and Cement Production

One of the key factors that contributes to the carbon emissions produced during ordinary Portland cement production is the high-temperature processing of clay and limestone. It is estimated that the global production of cement releases around 2 gigatonnes of carbon dioxide per year.

An alternative strategy to conventional limestone and cement production is the use of biogenic strategies, wherein biological organisms synthesize the building blocks of cement. This innovative approach utilizes microorganisms such as algae, which are fast-growing, cost-effective, sustainable, and extremely environmentally friendly.

Researchers Develop a Biogenic Limestone Production Route Using Microalgae

A research team from the University of Colorado Boulder recently published the results of their study into biogenic limestone which is grown using microalgae. One of the key benefits of using microalgae to produce biogenic limestone is that the organisms remove as much CO2 from the atmosphere as they grow as is produced by processing limestone, making this approach a carbon-neutral one.

The organisms which are central to this process are known as coccolithophores. These microalgae are cloudy white in color and use photosynthesis to store CO2 in a mineral form within themselves. Research has indicated that they are the largest producers of calcium carbonate out of any organism, outperforming even coral.

Image Credit: Aleksandr Pobedimskiy/Shutterstock.com

These organisms thrive in multiple marine environments, including warm, cold, fresh, and seawater. This makes them superior candidates for industrial-scale cultivation to produce biogenic limestone for use in cement production, providing the potential to completely replace conventional ordinary Portland cement.

In terms of land use, the researchers have stated that they estimate around one to two million acres will be needed to meet all the cement production needs in the US if these microalgae are grown in open ponds. To put this into perspective, this is only around 1-2% of land currently committed to corn production in the United States.

The team behind the research has noted that several options for growing coccolithophore production can be conducted in other options aside from open ponds, including vertical farms, continuous offshore production, and bioreactors.

Challenges and Future Outlook

The project team has stated that their technology has the maturity to address the environmental concerns of cement production. The key challenges are scalability and cost, which are being addressed through a $3.2 million dollar project.

Scaling the process and making it cost-competitive with conventional limestone production holds the potential for creating a truly sustainable construction industry of the future. This innovative biogenic limestone production route holds the potential for carbon-neutral cement production, and in conjunction with other green technologies such as the use of renewable energy during manufacture could even make the process carbon-negative.

Minus Materials is a start-up company that is commercializing the algae-grown, carbon-negative limestone developed by the researchers.

As Minus Materials, we imagine a world in which using more cement actually heals the planet. That’s our power — and our promise.

Dr. Wil Srubar, Founder and CEO of Minus Materials

As the world’s population surpasses 8 billion and the need for rapid urbanization and industrialization to meet the demands of this growing population figure accelerates, new sustainable technologies will be needed to ensure that industry can meet its net zero goals. Technologies such as this biogenic limestone production route will help to reduce the significant impact of construction on the planet.

More from AZoBuild: How do Construction Materials Age?

Further Reading and More Information

Cousins, S (2022) Limestone grown from algae can be used to make carbon-neutral cement [online] ribaj.com. Available at:

https://www.ribaj.com/products/microalgae-grown-limestone-for-concrete-university-of-colorado-boulder

Simpkins, K (2022) Cities of the future may be built with algae-grown limestone [online] Colorado.edu. Available at:

https://www.colorado.edu/today/2022/06/23/cities-future-may-be-built-algae-grown-limestone

ING (2021) Cement and climate change [online] ing.com. Available at:

https://www.ing.com/Newsroom/News/Cement-and-climate-change-.htm

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.