A research team in Switzerland recently constructed a geodesic dome made out of demolition waste to show how construction could become more sustainable by applying circular economy principles to waste and using digital technologies to facilitate this.

Image Credit: Nicole Davidson

Challenges for Construction

The construction industry is responsible for 11% of the world’s total carbon emissions, and the built environment as a whole creates 40% of the world’s total greenhouse gas emissions.

However, the world’s population is rising, climate change is making areas of the world uninhabitable, more people are moving into cities, and developing countries with growing populations need to build in order to approach the levels of safety and quality of life we expect to enjoy.

Recent studies have suggested that we must build enough floor space to cover New York City every month for the next 40 years to generate enough housing for 2060’s projected population.

Toward a Circular Economy for Construction Materials

Responding to these challenges, researchers are seeking better ways to build with reduced environmental harm.

Among these researchers is Catherine De Wolf, an assistant professor in ETH Zurich’s civil engineering department.

Speaking to AZO Build, De Wolf said: “The building design industry is the most resource-intensive, waste-generating, and polluting sector due to its linear extract-use-waste model. To remediate this, we urgently need a transition to a circular model, in which we reuse building materials.”

The circular economy is a conceptual intervention that seeks to move society past a linear model of resource use (“extract-use-waste”) to reuse materials instead. De Wolf and her colleagues in the Circular Engineering for Architecture (CEA) research group recently built a geodesic dome from building waste to demonstrate this idea and understand more about how to achieve this at scale.

Image Credit: ETH Zurich / Catherine De Wolf

Waste-Based Dome Project

De Wolf’s team began work on the waste-based dome project in October 2021, when they scoured a building in Geneva for materials before a scheduled demolition. With deconstruction experts on hand, De Wolf and three Ph.D. candidates working in the CEA group removed panels, wood beams, steel girders, and plastic piping from one floor of the building. They recovered enough materials to fill a small vehicle and brought them back to Zurich.

The team then designed a construction that could be built with these materials - a geodesic dome frame. The structure links wood beams together using ring-shaped connectors made from plastic piping. The assembly process took three days in total.

Teaching A New Generation of Architects and Engineers

De Wolf encouraged early-stage researchers in the CEA group to consider the entire lifecycle of construction materials’ use and reuse. This includes processes involved with dismantling former sites, designing with reused materials in mind, and actually assembling the final structure.

In this way, the project enabled researchers to understand what challenges and difficulties stand in the way of a transition to a circular economy for construction materials. This also gave the team opportunities to identify solutions to these challenges that might be applicable at larger scales.

Diese Kuppel besteht aus Abfall

Video Credit: ETH Zürich/Youtube.com

As well as providing the groundwork for original research and innovation in sustainable construction methods, the project also enabled De Wolf’s doctoral students to gain valuable skills that would empower them to continue to push the global construction sector toward a circular economy model.

By rebuilding a structure out of parts salvaged from a building set for demolition, students and researchers had the opportunity to directly apply digital innovations for circular construction in a real-world case study.

Catherine De Wolf, Circular Engineering for Architecture Group, ETH Zurich

The composition of the group is another way to achieve these aims. Members include architects, engineers, and computer scientists, each bringing their skills to bear on the problem of creating a circular economy for construction materials.

Digitization for Sustainability

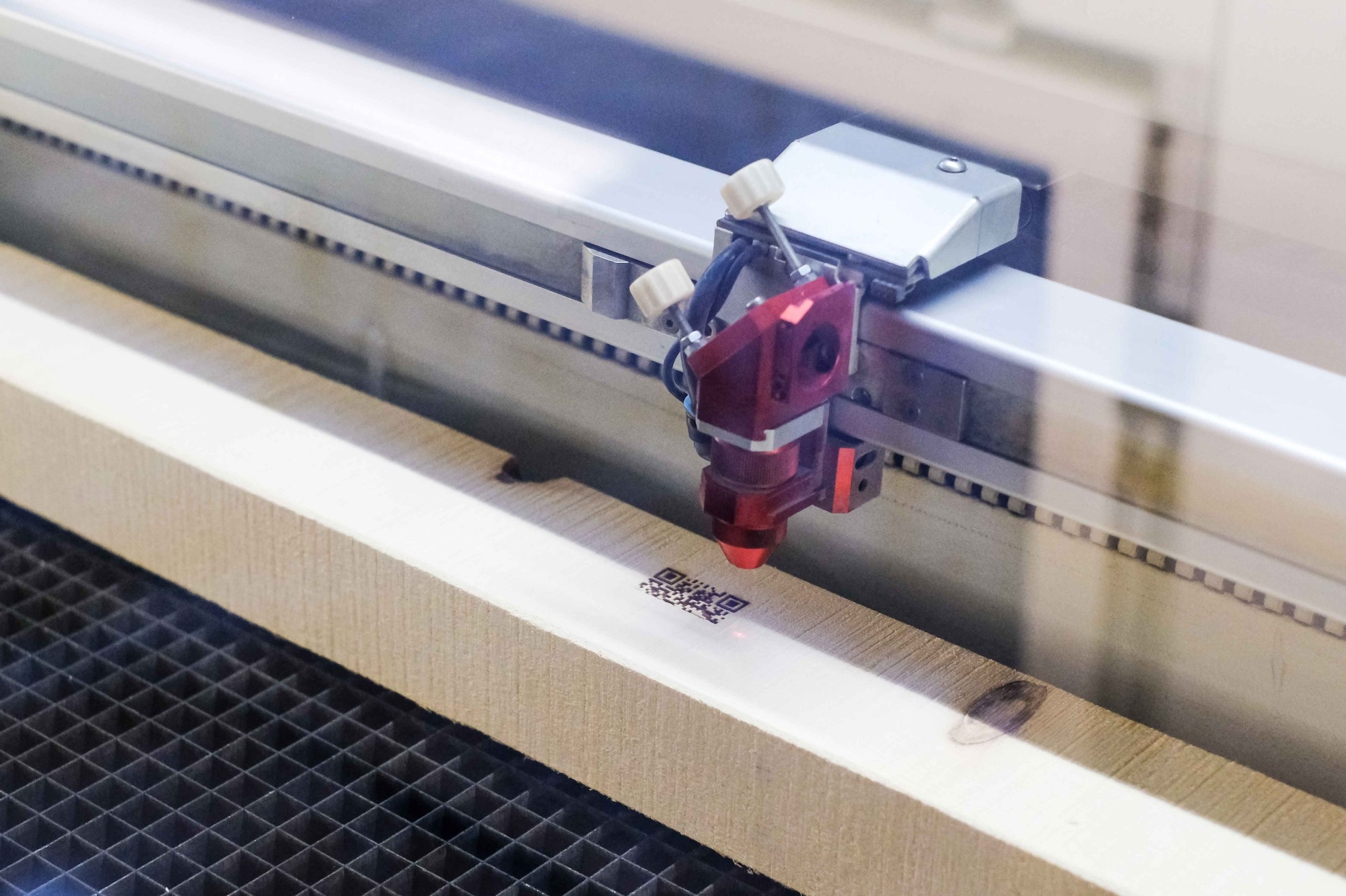

A key part of the project includes approaches to digitization in construction that can divert waste materials from landfill sites and return them as usable materials in new builds. A key aim of the project was to show how digitization could add value to construction processes.

De Wolf said: “The supply chain is extremely fragmented in the construction sector and adoption of digital innovation is slow. This dome project explores digital technologies ranging from AI to CNC milling as a means to achieving a much smarter and environmentally more responsible construction sector than ever before.”

In the dome project, digital approaches were implemented in every stage of the production process. The geodesic dome, for example, was designed to work with struts of varying lengths in order to achieve the most efficient use of recycled materials. A member of the research group wrote an algorithm that could calculate the ideal geometry and dimensions for the structure based on the wood that was available.

Image Credit: ETH Zurich / Catherine De Wolf

Another member of the team created an online platform for building materials, storing information about every piece of material used in the structure. This might be the basis for a digital marketplace in which demolition and construction would be able to meet in order to salvage materials more efficiently.

All these digital technologies have been used more and more in other sectors, and it is urgent to explore how they can also be used in the construction sector in order to increase the uptake of circular principles.

Catherine De Wolf, Circular Engineering for Architecture Group, ETH Zurich

How to Achieve A Circular Economy in Construction

Writing for the World Economic Forum recently, De Wolf also outlined key drivers of a circular economy for construction.

Digital models and platforms, such as the one designed by De Wolf’s doctoral student, are needed to automate circular construction. Building information modeling (BIM) goes some of the way toward this, but De Wolf appears to be arguing for a much more comprehensive materials dataset for every existing building.

Big Data approaches also need to come into play, alongside artificial intelligence (AI) techniques. De Wolf cited examples of machine learning algorithms developed by her PhD student to automatically detect reusable materials in images.

References and Further Reading

De Wolf, C. (2022). 4 promising digital technologies for circular construction. [Online] World Economic Forum. Available at: https://www.weforum.org/agenda/2022/09/4-promising-digital-technologies-for-circular-construction/

Künzler, R. (2022). A wooden dome made solely from waste. [Online] ETH Zurich. Available at: https://ethz.ch/en/news-and-events/eth-news/news/2022/04/globe-a-wooden-dome-made-solely-from-waste.html#comment-system

Pilkington, B. (2021). Green Building: Where Are We Now? [Online] AZO Build. Available at: https://www.azobuild.com/article.aspx?ArticleID=8453

---. (2019). How the Building Industry is Improving its Use of Clean Technology. [Online] AZO Build. Available at: https://www.azobuild.com/article.aspx?ArticleID=8355

Winther, K. The future is a digital, circular construction process. [Online] Arup. Available at: https://www.arup.com/perspectives/the-future-is-a-digital-circular-construction-process

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.