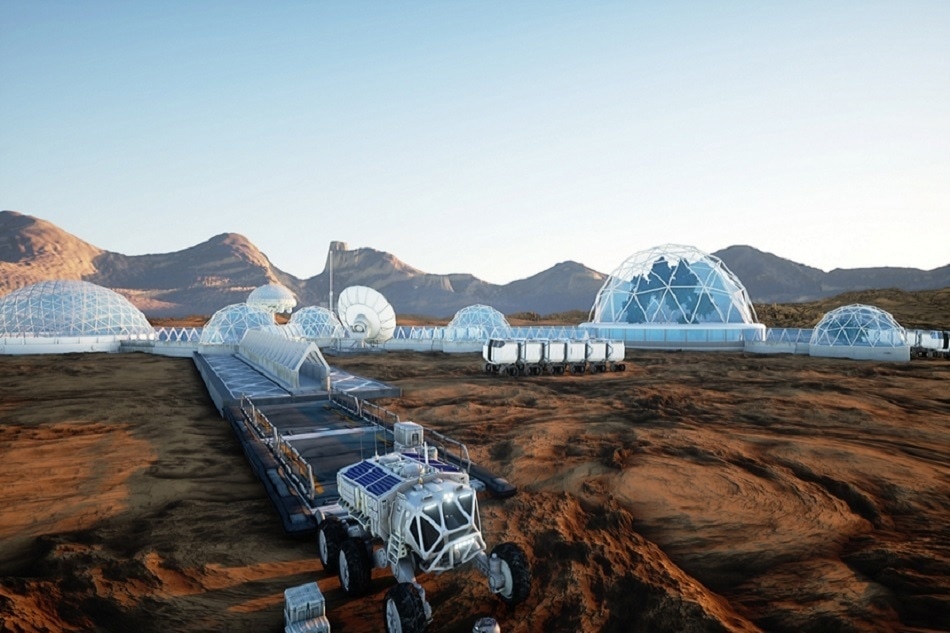

A closed waterway system with an artificial waterfall, soil that provides ongoing nutrients, oxygen and water and 3D printed, programmed construction, suited-for-conditions buildings

What do these ideas have in common? They are part of the Mars City Design project that solicits proposals on cities for Mars.

Initial Judges of the work are: Rob Manning, Chief Engineer for US Mars Missions at National Aeronautics and Space Administration (NASA), Pierre-Philippe Mathieu, an Earth Observation Data Scientist at the European Space Agency in ESRIN (Frascati, Italy), and Steven Madge, a Vice President at Dassault Systems. Ultimately out of 25 Finalists, three will be chosen.

Project Creator Vera Mulyani envisions using 3D printing to produce real-life versions of designs that are then tested in the Mojave Desert. Mulyani’s mission is to have at least four people fly to Mars when it is possible and set up a sustainable city for at least 1,000 inhabitants. Yet there are many questions about how the materials and constructions would fare on Mars.

What is known is that gravity is different on Mars that the density of materials must in some way compensate. Also the designs incorporate means of power and food generation on a harsh planet which is remote—at 140 million miles from Earth. With water known to be on Mars, however, many Scientists and Space Travel Financiers, including Elon Musk, are predicting colonization in the next 100 years

Beginning in the early 2000s with a grant from NASA, the Mars City project was originally envisioned as a STEM learning program. Today, Architects, Engineers, and Designers are working on a variety of projects in part through support from a non-profit organization called Mars City Foundation.

Central to some of the Mars city designs are rooms in buildings that are de-linked from the outside environment and that are insulated from multiple systems failures.

One winning design is Project Dandelion. Carnegie Mellon Architecture Student Gabriel José Vidal Hallett’s creation is a mushroom-cap-shaped large capsule that uses the most of the Martian soil element regolith for oxygen, water and other life support elements. To be sustainable, in addition to thinking about energy from a ground drill with geothermal coils and using septic composters and inside wild farms, the Architect has planned for spaces for humans to be as active and stimulated as possible during long visits.

In another Mars design contest, NASA chose three teams in 2015 out of 165 entrants through its 3-D Printed Habitat Challenge Design Competition at the New York Maker Faire. Top on the list with a $25,000 award was Team Space Exploration Architecture and Clouds Architecture Office of New York, New York, for the design Mars Ice House. The ice house features a process whereby subsurface ice’s water vapor is used as liquid water in a robotic 3D printing process to form solid ice panels.

Specifically, a robotic machine is used to sort through soil to collect dust and extract water and form ice. A laser cuts the ice into panels while any remaining is stored for other uses.

The 3D-printed Habitat Challenge has three phases with Phase 1 having begun as a 2015 completed Design Competition; Phase 2 as a Structural Member Competition with $1.1 million prize money on the materials and technologies required for the best structural features; and Phase 3 as an On-Site Habitat Competition with a $1.4 million prize and a focus on fabrication technologies.

Subscribe to our Newsletters

Subscribe to our Newsletters

Sources:

Image Credit:

Shutterstock.com/PavelChagochkin

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.